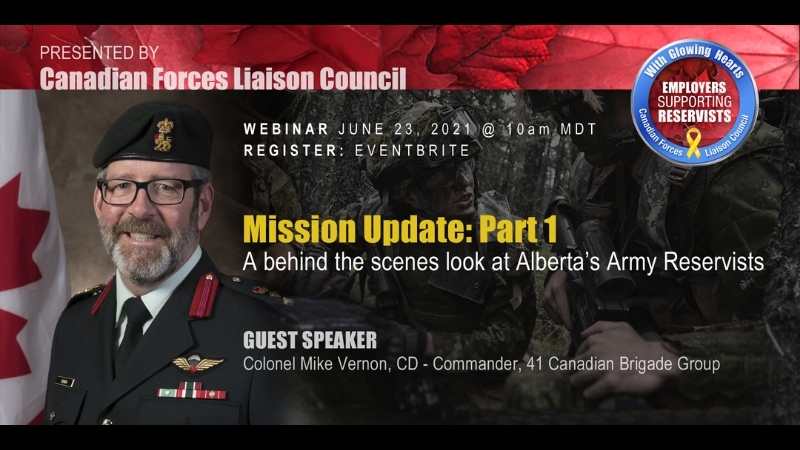

Alberta

Mission Update: A behind the scenes look at Alberta’s Army Reservists

Submitted by: Canadian Forces Liaison Council

Join us for an informative webinar on June 23rd with guest speaker Colonel Mike Vernon, CD/Commander of 41 Canadian Brigade Group.

A behind the scenes look at who reservists are, what they do, and how the Alberta Reserve is preparing and training to support our communities and country when we need them most.

Numerous Alberta businesses employ individuals who are members of the Reserve Force. When Alberta faces a disaster – the Covid-19 Pandemic, fires, floods – reservists are asked to respond to the call and assist in the survival and support of our communities. Responding to these calls often pulls reservists away from their regular employment.

Reservists are skilled and talented people who are part-time “citizen soldiers”, sailors and airmen/airwomen. In addition to their military responsibilities, they also work full time in the civilian workforce. They enhance corporate culture, small and large businesses, with the experience they have attained in the military. As a candidate for a position they have a well-earned skill set that goes above and beyond another candidate for the same role. If you already employ a Reservist, you know the benefits they bring to the workplace with both hard and soft skills.

The Canadian Armed Forces provide Reservists with world class training to develop key skills which form not only the foundations of an valuable Reservist but also a highly qualified employee. Employers benefit from their core skills and abilities such as leadership, teamwork, discipline, initiative, determination, problem solving, and the ability to work under pressure.

When you employ a Reservist, they bring their learnings from the military to your organization. In turn, they also contribute their workplace expertise when serving in the military. It’s a win-win for both the organization and the Canadian Armed Forces. Reservists who serve help to provide a safe environment for businesses to thrive and is one of the very reasons many people are proud of our serving members.

The Basics

Reservists are members of the Canadian Armed Forces (CAF) who train and serve with the CAF on a part-time basis. They typically serve on weekday evenings and weekends. From time to time Reservists attend military courses and training that lasts one or two weeks and occasionally longer durations. Reservists have the opportunity to volunteer to serve on domestic and international operations on a full-time basis augmenting the regular component of the CAF. Through floods, fires or ice storms, Reservists are there to help and to keep communities and businesses operating. Their training provides both domestic response and international support – when you employ a Reservist, you in turn, are serving your country.

What is the With Glowing Hearts Initiative?

The With Glowing Hearts – Reservist Support Initiative is an HR program to attract and retain talented employees. The Canadian Armed Forces has trained over 25,000 Reservists who bring exceptional qualifications to an organization or business. Consider the Reserves as a talent pool to source potential employees to support company goals and initiatives. The initiative provides guidance and tools to support both Employers and Reservists and the good work they do together. Employing a Reservist is good for business and it makes your work, and workplace, better – With Glowing Hearts, we stand together supporting our community and country.

How does the program work?

It’s simple – like any other HR initiative, the program becomes an offering to attract employees. For example, a company may already have a maternity leave policy in place, growth programs for leadership, or even policies for internships. The With Glowing Hearts – Reservist Support Initiative creates a “reserve-friendly” culture for an organization to attract, and keep, experienced and valued employees. The turnkey program assets can be used to create awareness through communication channels of choice.

What does the program include?

The program consists of the following elements:

- Reservists 101: What Reservists offer Employers

- “With Glowing Hearts” Reservist support customized certificate for Employers

- “With Glowing Hearts” Employer/Reservist Recognition stickers

- “With Glowing Hearts” Customized employer support icon (online use)

- HR & FAQS: Q&A for employing Reservists

- Military Leave Policy (MLP): Examples of MLP for small and large businesses

What’s next?

- Register for the program or for more information: cflcwithglowinghearts.ca

How can I find out more information for my business?

Employers Supporting Reservists – Canadian Forces Liaison Council

Visit the website: https://www.canada.ca/en/department-national-defence/services/benefits-military/supporting-reservists-employers.html

Alberta

Alberta school boards required to meet new standards for school library materials with regard to sexual content

Alberta’s government has introduced new standards to ensure school library materials are age-appropriate.

School libraries should be safe and supportive places where students can learn and explore without being exposed to inappropriate sexual content. However, in the absence of a consistent standard for selecting age-appropriate library materials, school boards have taken different approaches, leading to concerns about safeguards in place.

In response to these concerns, and informed by feedback from education partners and the public, Alberta’s government has created standards to provide school boards with clear direction on the selection, availability and access to school library materials, such as books.

“Our actions to ensure that materials in school libraries don’t expose children to sexual content were never about banning books. These new standards are to ensure that school boards have clear guidance to ensure age-appropriate access to school library materials, while reflecting the values and priorities of Albertans.”

The new standards set clear expectations for school library materials with regard to sexual content and require school boards to implement policies to support these standards.

Standards for school library materials

Under the new standards, school libraries are not permitted to include library materials containing explicit sexual content. Non-explicit sexual content may be accessible to students in Grade 10 and above, provided it is age-appropriate.

“Protecting kids from explicit content is common sense. LGBTQ youth, like all children, deserve to see themselves in stories that are age-appropriate, supportive and affirming – not in material that sexualizes or confuses them.”

School boards must also regularly review their school library collections, publish a full list of available materials and ensure that a staff member supervises students’ access to school library materials. School boards will have to remove any materials with explicit sexual content from their school libraries by October 1.

School board policies and procedures

All school boards must have publicly available policies that align with the new standards for selecting and managing library materials by January 1, 2026. School boards can either create new policies or update existing ones to meet these requirements.

These policies must outline how school library materials are selected and reviewed, how staff supervise students’ access throughout the school day, and how a student, parent, school board employee or other member of the school community can request a review or removal of materials in the school library. School boards are also required to clearly communicate these policies to employees, students and parents before January 2026.

“A robust, grade- and age-appropriate library catalogue is vital for student success. We welcome the ministry’s initiative to establish consistent standards and appreciate the ongoing consultation to help craft a plan that will serve our families and communities well.”

“Red Deer Public Schools welcomes the new provincial standards for school library materials. Our division is committed to maintaining welcoming, respectful learning spaces where students can grow and thrive. Under the new standards for school libraries, we remain dedicated to providing learning resources that reflect our values and support student success.”

Quick facts

- The new standards will apply to public, separate, francophone, charter and independent schools.

- The ministerial order does not apply to municipal libraries located within schools or materials selected for use by teachers as learning and teaching resources.

- From May 26 to June 6, almost 80,000 people completed an online survey to provide feedback on the creation of consistent standards to ensure the age-appropriateness of materials available to students in school libraries.

Related information

- Ministerial Order

- School library standards engagement

- Reference Materials: Content warning: this document contains graphic content that may be disturbing to viewers and is not appropriate for young viewers. Viewer discretion is advised.

Alberta

Fourteen regional advisory councils will shape health care planning and delivery in Alberta

Regional health councils give Albertans a voice

Albertans want a health care system that reflects where they live and adapts to the unique needs of their communities. As part of the province’s health care refocus, Alberta’s government committed to strengthening community voices by providing more opportunities for Albertans to bring forward their local priorities and offer input on how to improve the system.

The regional advisory councils, made up of 150 members from 71 communities, will advise Alberta’s four health ministries and the newly refocused health agencies: Primary Care Alberta, Acute Care Alberta, Assisted Living Alberta and Recovery Alberta. Each council will explore solutions to local challenges and identify opportunities for the health system to better support community decision-making.

“By hearing first-hand community feedback directly, we can build a system that is more responsive, more inclusive and ultimately more effective for everyone. I am looking forward to hearing the councils’ insights, perspectives and solutions to improve health care in all corners of our province.”

“Regional advisory councils will strengthen acute care by giving communities a direct voice. Their insights will help us address local needs, improve patient outcomes and ensure timely access to hospital services.”

“A ‘one-size-fits-all’ approach does not address unique regional needs when it comes to mental health and addiction challenges. These councils will help us hear directly from communities, allowing us to tailor supports and services to meet the needs of Albertans where they are.”

“Every community has unique needs, especially when it comes to seniors and vulnerable populations. These regional advisory councils will help us better understand those needs and ensure that assisted living services are shaped by the people who rely on them.”

Members include Albertans from all walks of life, health care workers, community leaders, Indigenous and municipal representatives, and others with a strong tie to their region. About one-third of members work in health care, and more than half of the council chairs are health professionals. Almost one-quarter are elected municipal officials, including 10 serving as chairs or vice-chairs. Ten councils also include a representative from a local health foundation.

Council members will share local and regional perspectives on health care services, planning and priorities to help ensure decisions reflect the realities of their communities. By engaging with residents, providers and organizations, they will gather feedback, identify challenges and bring forward ideas that may not otherwise reach government.

Through collaboration and community-informed solutions, members will help make the health system more responsive, accessible and better able to meet the needs of Albertans across the province.

“As Primary Care Alberta works to improve access to primary health care services and programs across Alberta, we are grateful to have the opportunity to tap into a dedicated group of community leaders and representatives. These people know their communities and local needs, and we look forward to learning from their experiences and knowledge as we shape the future of primary care in Alberta.”

“The regional advisory councils will help to bring forward the voices of patients, families and front-line providers from every corner of Alberta. Their insights will help us plan smarter and deliver care that’s timely, effective and truly local. We look forward to working closely with them to strengthen hospital and surgical services across the province.”

“Nobody understands the health care challenges unique to a community better than the people who live there. The regional health advisory councils are made up of those living and working on the front lines across the province, ensuring we are getting the perspective of Albertans most affected by our health care system.”

“Alongside Recovery Alberta’s staff and physician team, these regional advisory councils will build upon the high standard of mental health, addiction and correctional health services delivered in Alberta.”

Indigenous Advisory Council

Alberta’s government continues to work directly with Indigenous leaders across the province to establish the Indigenous Advisory Council to strengthen health care services for First Nation, Métis and Inuit communities.

With up to 22 members, including Indigenous health care workers, community leaders and individuals receiving health care services, the council will represent diverse perspectives across Alberta. Members will provide community perspectives about clinical service planning, capital projects, workforce development and cultural integration in health care.

Related information

-

Also Interesting2 days ago

Also Interesting2 days ago9 Things You Should Know About PK/PD in Drug Research

-

Business2 days ago

Business2 days ago‘Experts’ Warned Free Markets Would Ruin Argentina — Looks Like They Were Dead Wrong

-

Business2 days ago

Business2 days agoCannabis Legalization Is Starting to Look Like a Really Dumb Idea

-

Business2 days ago

Business2 days agoWEF-linked Linda Yaccarino to step down as CEO of X

-

Bruce Dowbiggin1 day ago

Bruce Dowbiggin1 day agoThe Covid 19 Disaster: When Do We Get The Apologies?

-

Media1 day ago

Media1 day agoCBC journalist quits, accuses outlet of anti-Conservative bias and censorship

-

Business1 day ago

Business1 day agoCarney government should recognize that private sector drives Canada’s economy

-

Automotive2 days ago

Automotive2 days agoAmerica’s EV Industry Must Now Compete On A Level Playing Field