Alberta

Clean tech innovation cuts emissions, creates jobs

March 12, 2019

Alberta’s Climate Leadership Plan is helping major industries reduce emissions and create jobs while cutting costs and becoming more competitive.

Emissions Reduction Alberta is funding more than a dozen new clean technology projects across the province, while Energy Efficiency Alberta is supporting small and medium-sized oil and gas companies to reduce methane emissions through upgrades.

“Innovation is a key part of Alberta’s economic and environmental success, and our industries continue to show tremendous leadership. Clean technology investments lead to made-in-Alberta solutions that support jobs, protect our environment, and point Alberta toward a healthy, prosperous future.”

Emissions Reduction Alberta (ERA)

From Fort McMurray to Waterton, 16 innovative clean technology projects will receive funding through ERA’s $100-million Biotechnology, Electricity and Sustainable Transportation (BEST) Challenge – the largest challenge in ERA’s history.

These projects have a combined value of $600 million and the potential to reduce a total of 2.5 million tonnes of greenhouse gas emissions by 2030 – the same as taking 530,700 cars off the road. These projects will also result in 114 new jobs.

“Our BEST Challenge is about accelerating the most promising clean technology solutions across multiple sectors – from new solar opportunities in coal-impacted communities to efficient fleet solutions. These projects will be a showcase for innovative technologies that can be adopted in communities across Alberta. They support economic growth, community health and demonstrate environmental leadership on a national and global scale.”

The Alberta Motor Transport Association (AMTA) is working to develop and demonstrate a 700-kilometre-plus-range zero emission truck. These trucks will reduce greenhouse gas emissions through improved fuel efficiency of the fuel cell hybrid drivetrain. Sequestering carbon at the hydrogen generation facility will result in even greater emissions reductions.

“This is a very exciting project for the AMTA and our member companies. This initiative is primarily about moving freight on Alberta’s highways with zero emissions, but it is also about the future of the Alberta economy. Alberta is in the transportation fuel business, and that business is changing. The AZETEC project demonstrates that Alberta’s commercial transportation industry is leading the transition towards innovative, zero-emission transportation that meets the province’s unique needs.”

Another funding recipient, eCAMION, is working on a project to transition Alberta’s buses from diesel to electric. Its first-of-a-kind charging system could lower installation and operating costs, encouraging broader and faster adoption across the province. eCAMION will partner with the City of Edmonton on a trial of its fast-charge technology. A complete list of BEST Challenge projects is available here.

Energy Efficiency Alberta (EEA)

Government is providing an additional $5 million to support the continued success of EEA’s popular $10-million Methane Emissions Reduction initiative.

The program has already made it easier for 30 small and medium-sized oil and gas companies to address methane waste through energy-efficient equipment upgrades, which also helps facilities hire more staff, reduce annual emissions and boost competitiveness. To date, 2,534 applications are approved, with at least 1,500 more anticipated by March 31, 2019.

“Through methane-reduction education and deployment of existing technologies, companies ultimately have the ability to become more competitive and efficient. This announcement will result in a great collaboration to further our methane-reduction programming for the oil and gas sector.”

The funding boost will also support a $1.5-million grant for the Petroleum Technology Alliance of Canada to introduce technologies that reduce methane emissions. The grant is expected to reduce up to 200,000 tonnes of emissions – the same as taking 42,460 cars off the road.

“Energy Efficiency Alberta’s Methane Emissions Reduction initiative is a momentous step towards a massive deployment of proven, cost-effective, economic methane-mitigation technologies that will benefit our people, planet and industry. It will enable producers – large and small – to maintain competitiveness, while helping Alberta’s entrepreneurs and small technology providers prosper and create jobs.”

“EEA’s Methane Emissions Reduction Program continues to improve the province’s emissions inventory while growing local jobs and incentivizing capital investment in Alberta-based emission-reduction projects. We look forward to continuing to contribute to the success of this program and working with industry to implement emission-reduction technologies.”

Quick facts

- The biotechnology, electricity and sustainable transportation sectors account for more than 40 per cent of Alberta’s annual greenhouse gas emissions.

- ERA takes action on climate change and supports economic growth and diversification by investing carbon pricing paid by industry directly into clean technology solutions that reduce emissions, attract investment and create jobs. To date, ERA has committed more than $572 million in funding to 164 projects with a total value of roughly $4.3 billion.

- The climate change impact of methane is 25 times greater than carbon dioxide over a 100-year period. Methane emissions in 2014 from Alberta’s oil and gas sector accounted for 70 per cent of provincial methane emissions, and 25 per cent of all emissions from the upstream oil and gas sector.

- The Methane Emissions Reduction Program was announced in October 2018, and 60 per cent of the first year’s budget has already been committed. The program received three dozen applications in the first six weeks.

Alberta

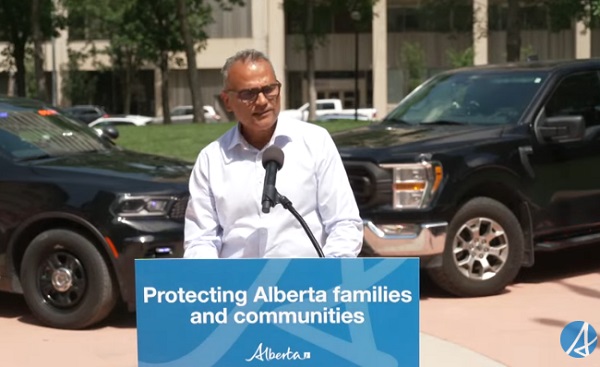

Alberta Provincial Police – New chief of Independent Agency Police Service

Sat Parhar has been appointed as the first chief of the Independent Agency Police Service, marking the next step toward a new municipal policing option.

The appointment of a new chief for the Independent Agency Police Service (IAPS) marks the next step in giving municipalities a new option for local policing and builds on the work already underway for the agency to assume the police-like duties currently carried out by the Alberta Sheriffs. The IAPS will empower municipalities to adopt strategies that effectively respond to their specific safety concerns, enhancing public safety across the province.

Chief Parhar brings more than 25 years of policing experience, including senior roles with the Calgary Police Service, most recently as deputy chief. His frontline policing experience and deep understanding of Alberta’s complex and diverse public safety landscape positions him to lead the agency as it takes shape and begins its work as a new municipal policing option, keeping communities safe.

Once operational, the agency will strengthen Alberta’s existing policing model and complement the province’s current police services, which includes the RCMP, Indigenous policing services and municipal police. It will help fill gaps and ensure law enforcement resources are deployed efficiently to meet Alberta’s evolving public safety needs and improve law enforcement response times, particularly in rural communities.

“Appointing Chief Sat Parhar is a key milestone in Alberta’s plan to give municipalities a real choice in how their communities are kept safe. This is about building a modern police service that reflects the priorities of Albertans, strengthens local decision-making, and ensures every corner of our province, especially rural areas, can count on responsive, effective law enforcement. With his decades of experience and deep understanding of Alberta’s policing landscape, he is the right leader to bring this vision to life.”

“This appointment signifies a significant step forward in our efforts to establish a more robust, community-focused policing model that is better equipped to meet the unique needs of our local residents. Under Chief Parhar’s visionary leadership, we are confident that we will develop a modern, efficient police service that not only enhances public safety but also aligns closely with the priorities and values of Albertans. His experience and commitment are vital in shaping an IAPS that is responsive, transparent, and dedicated to fostering trust and collaboration within the community, ultimately ensuring a safer and more connected society for all.”

Chief Parhar’s immediate priorities will be to hire an executive team and commence organizational planning such as developing key recruitment, training and other operational policies. Chief Parhar’s appointment is the first step of many to establishing the IAPS.

“It’s an honour to take on this role and help shape a modern police service built for Alberta. My focus from day one will be on setting high standards for professionalism, building strong relationships with our partners and ensuring this service reflects the needs and priorities of the communities we serve.”

The Independent Agency Police Service was formally created through regulation following the passing of Public Safety Statutes Amendment Act, 2024. The agency will operate as an independent Crown corporation, and will be renamed the Alberta Sheriffs Police Service, with its head office located in Calgary. The IAPS will be operationally independent from the provincial government with civilian oversight, consistent with all police services in Alberta.

“When it comes to policing, municipalities like ours deserve a choice – especially when the current system leaves us disadvantaged simply because of our size. We look forward to learning more about what that alternative will look like once an Alberta police agency is fully established and the options are clear. For us, this is about fairness, sustainability, and ensuring municipalities have access to policing solutions that reflect both their needs and their realities.”

Quick facts

- The regulation establishes the IAPS Provincial Corporation and its governance structure including board of directors, board of director powers, financial responsibilities and accountabilities.

Related news

- Expanding municipal police service options (April 7, 2024)

Alberta

Pierre Poilievre – Per Capita, Hardisty, Alberta Is the Most Important Little Town In Canada

From Pierre Poilievre

-

Business2 days ago

Business2 days agoOttawa Funded the China Ferry Deal—Then Pretended to Oppose It

-

COVID-192 days ago

COVID-192 days agoNew Peer-Reviewed Study Affirms COVID Vaccines Reduce Fertility

-

MAiD2 days ago

MAiD2 days agoCanada’s euthanasia regime is not health care, but a death machine for the unwanted

-

Alberta2 days ago

Alberta2 days agoThe permanent CO2 storage site at the end of the Alberta Carbon Trunk Line is just getting started

-

Business1 day ago

Business1 day agoWorld Economic Forum Aims to Repair Relations with Schwab

-

Alberta1 day ago

Alberta1 day agoAlberta’s government is investing $5 million to help launch the world’s first direct air capture centre at Innisfail

-

Business2 days ago

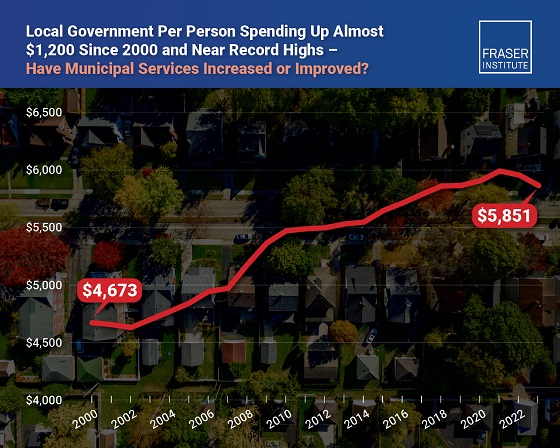

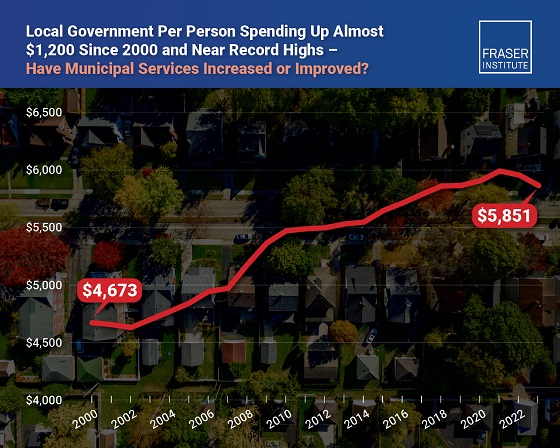

Business2 days agoMunicipal government per-person spending in Canada hit near record levels

-

Business1 day ago

Business1 day agoA new federal bureaucracy will not deliver the affordable housing Canadians need