Canadian Energy Centre

Why Canadian oil is so important to the United States

From the Canadian Energy Centre

Complementary production in Canada and the U.S. boosts energy security

The United States is now the world’s largest oil producer, but its reliance on oil imports from Canada has never been higher.

Through a vast handshake of pipelines and refineries, Canadian oil and U.S. oil complement each other, strengthening North American energy security.

Here’s why.

Decades in the making

Twenty years ago, the North American energy market looked a lot different than it does today.

In the early 2000s, U.S. oil production had been declining for more than 20 years. By 2005, it dropped to its lowest level since 1949, according to the U.S. Energy Information Administration (EIA).

America’s imports of oil from foreign nations were on the rise.

But then, the first of two powerhouse North American oil plays started ramping up.

In Canada’s oil sands, a drilling technology called SAGD – steam-assisted gravity drainage – unlocked enormous resources that could not be economically produced by the established surface mining processes. And the first new mines in nearly 25 years started coming online.

In about 2010, the second massive play – U.S. light, tight oil – emerged on the scene, thanks to hydraulic fracturing technology.

Oil sands production jumped from about one million barrels per day in 2005 to 2.5 million barrels per day in 2015, reaching an average 3.5 million barrels per day last year, according to the Canada Energy Regulator.

Meanwhile, U.S. oil production skyrocketed from 5.5 million barrels per day in 2005 to 9.4 million barrels per day in 2015 and 13.3 million barrels per day in 2024, according to the EIA.

Together the United States and Canada now produce more oil than anywhere else on earth, according to S&P Global.

As a result, overall U.S. foreign oil imports declined by 35 per cent between 2005 and 2023. But imports from Canada have steadily gone up.

In 2005, Mexico, Saudi Arabia, Venezuela and Nigeria together supplied 52 per cent of U.S. oil imports. Canada was at just 16 per cent.

In 2024, Canada supplied 62 per cent of American oil imports, with Mexico, Saudi Arabia and Venezuela together supplying just 14 per cent, according to the EIA.

“Light” and “heavy” oil

Canadian and U.S. oil production are complementary because they are different from each other in composition.

Canada’s oil exports to the U.S. are primarily “heavy” oil from the oil sands, while U.S. production is primarily “light” oil from the Permian Basin in Texas and New Mexico.

One way to think of it is that heavy oil is thick and does not flow easily, while light oil is thin and flows freely – like orange juice compared to fudge.

The components that make the oil like this require different refinery equipment to generate products including gasoline, jet fuel and base petrochemicals.

Of the oil the U.S. imported from Canada from January to October last year, 75 per cent was heavy, six per cent was light, and the remaining 19 per cent was “medium,” which basically has qualities in between the two.

Tailored for Canadian crude

Many refineries in the United States are specifically designed to process heavy oil, primarily in the U.S. Midwest and U.S. Gulf Coast.

Overall, there are about 130 operable oil refineries in the United States, according to the American Fuel and Petrochemical Manufacturers.

The Alberta Petroleum Marketing Commission (APMC) estimates that 25 consistently use oil from Alberta.

According to APMC, the top five U.S. refineries running the most Alberta crude are:

- Marathon Petroleum, Robinson, Illinois (100% Alberta crude)

- Exxon Mobil, Joliet, Illinois (96% Alberta crude)

- CHS Inc., Laurel, Montana (95% Alberta crude)

- Phillips 66, Billings, Montana (92% Alberta crude)

- Citgo, Lemont, Illinois (78% Alberta crude)

Since 2010, virtually 100 per cent of oil imports to the U.S. Midwest have come from Canada, according to the EIA.

In recent years, new pipeline access and crude-by-rail have allowed more Canadian oil to reach refineries on the U.S. Gulf Coast, rising from about 140,000 barrels per day in 2010 to about 450,000 barrels per day in 2024.

U.S. oil exports

The United States banned oil exports from 1975 to the end of 2015. Since, exports have surged, averaging 4.1 million barrels per day last year, according to the EIA.

That is nearly equivalent to the 4.6 million barrels per day of Canadian oil imported into the U.S. over the same time period, indicating that Canadian crude imports enable sales of U.S. oil to global markets.

Future outlook

Twenty-five years from now, the U.S. will need to import virtually exactly the same amount of oil as it does today (7.0 million barrels per day in 2050 compared to 6.98 million barrels per day in 2023), according to the EIA.

Business

Why it’s time to repeal the oil tanker ban on B.C.’s north coast

The Port of Prince Rupert on the north coast of British Columbia. Photo courtesy Prince Rupert Port Authority

From the Canadian Energy Centre

By Will Gibson

Moratorium does little to improve marine safety while sending the wrong message to energy investors

In 2019, Martha Hall Findlay, then-CEO of the Canada West Foundation, penned a strongly worded op-ed in the Globe and Mail calling the federal ban of oil tankers on B.C.’s northern coast “un-Canadian.”

Six years later, her opinion hasn’t changed.

“It was bad legislation and the government should get rid of it,” said Hall Findlay, now director of the University of Calgary’s School of Public Policy.

The moratorium, known as Bill C-48, banned vessels carrying more than 12,500 tonnes of oil from accessing northern B.C. ports.

Targeting products from one sector in one area does little to achieve the goal of overall improved marine transport safety, she said.

“There are risks associated with any kind of transportation with any goods, and not all of them are with oil tankers. All that singling out one part of one coast did was prevent more oil and gas from being produced that could be shipped off that coast,” she said.

Hall Findlay is a former Liberal MP who served as Suncor Energy’s chief sustainability officer before taking on her role at the University of Calgary.

She sees an opportunity to remove the tanker moratorium in light of changing attitudes about resource development across Canada and a new federal government that has publicly committed to delivering nation-building energy projects.

“There’s a greater recognition in large portions of the public across the country, not just Alberta and Saskatchewan, that Canada is too dependent on the United States as the only customer for our energy products,” she said.

“There are better alternatives to C-48, such as setting aside what are called Particularly Sensitive Sea Areas, which have been established in areas such as the Great Barrier Reef and the Galapagos Islands.”

The Business Council of British Columbia, which represents more than 200 companies, post-secondary institutions and industry associations, echoes Hall Findlay’s call for the tanker ban to be repealed.

“Comparable shipments face no such restrictions on the East Coast,” said Denise Mullen, the council’s director of environment, sustainability and Indigenous relations.

“This unfair treatment reinforces Canada’s over-reliance on the U.S. market, where Canadian oil is sold at a discount, by restricting access to Asia-Pacific markets.

“This results in billions in lost government revenues and reduced private investment at a time when our economy can least afford it.”

The ban on tanker traffic specifically in northern B.C. doesn’t make sense given Canada already has strong marine safety regulations in place, Mullen said.

Notably, completion of the Trans Mountain Pipeline expansion in 2024 also doubled marine spill response capacity on Canada’s West Coast. A $170 million investment added new equipment, personnel and response bases in the Salish Sea.

“The [C-48] moratorium adds little real protection while sending a damaging message to global investors,” she said.

“This undermines the confidence needed for long-term investment in critical trade-enabling infrastructure.”

Indigenous Resource Network executive director John Desjarlais senses there’s an openness to revisiting the issue for Indigenous communities.

“Sentiment has changed and evolved in the past six years,” he said.

“There are still concerns and trust that needs to be built. But there’s also a recognition that in addition to environmental impacts, [there are] consequences of not doing it in terms of an economic impact as well as the cascading socio-economic impacts.”

The ban effectively killed the proposed $16-billion Eagle Spirit project, an Indigenous-led pipeline that would have shipped oil from northern Alberta to a tidewater export terminal at Prince Rupert, B.C.

“When you have Indigenous participants who want to advance these projects, the moratorium needs to be revisited,” Desjarlais said.

He notes that in the six years since the tanker ban went into effect, there are growing partnerships between B.C. First Nations and the energy industry, including the Haisla Nation’s Cedar LNG project and the Nisga’a Nation’s Ksi Lisims LNG project.

This has deepened the trust that projects can mitigate risks while providing economic reconciliation and benefits to communities, Dejarlais said.

“Industry has come leaps and bounds in terms of working with First Nations,” he said.

“They are treating the rights of the communities they work with appropriately in terms of project risk and returns.”

Hall Findlay is cautiously optimistic that the tanker ban will be replaced by more appropriate legislation.

“I’m hoping that we see the revival of a federal government that brings pragmatism to governing the country,” she said.

“Repealing C-48 would be a sign of that happening.”

Alberta

The permanent CO2 storage site at the end of the Alberta Carbon Trunk Line is just getting started

Wells at the Clive carbon capture, utilization and storage project near Red Deer, Alta. Photo courtesy Enhance Energy

From the Canadian Energy Centre

Inside Clive, a model for reducing emissions while adding value in Alberta

It’s a bright spring day on a stretch of rolling farmland just northeast of Red Deer. It’s quiet, but for the wind rushing through the grass and the soft crunch of gravel underfoot.

The unassuming wellheads spaced widely across the landscape give little hint of the significance of what is happening underground.

In just five years, this site has locked away more than 6.5 million tonnes of CO₂ — equivalent to the annual emissions of about 1.5 million cars — stored nearly four CN Towers deep beneath the surface.

The CO₂ injection has not only reduced emissions but also breathed life into an oilfield that was heading for abandonment, generating jobs, economic activity and government revenue that would have otherwise been lost.

This is Clive, the endpoint of one of Canada’s largest carbon capture, utilization and storage (CCUS) projects. And it’s just getting started.

Rooted in Alberta’s first oil boom

Clive’s history ties to Alberta’s first oil boom, with the field discovered in 1952 along the same geological trend as the legendary 1947 Leduc No. 1 gusher near Edmonton.

“The Clive field was discovered in the 1950s as really a follow-up to Leduc No. 1. This is, call it, Leduc No. 4,” said Chris Kupchenko, president of Enhance Energy, which now operates the Clive field.

Over the last 70 years Clive has produced about 70 million barrels of the site’s 130 million barrels of original oil in place, leaving enough energy behind to fuel six million gasoline-powered vehicles for one year.

“By the late 1990s and early 2000s, production had gone almost to zero,” said Candice Paton, Enhance’s vice-president of corporate affairs.

“There was resource left in the reservoir, but it would have been uneconomic to recover it.”

Gearing up for CO2

Calgary-based Enhance bought Clive in 2013 and kept it running despite high operating costs because of a major CO2 opportunity the company was developing on the horizon.

In 2008, Enhance and North West Redwater Partnership had launched development of the Alberta Carbon Trunk Line (ACTL), one of the world’s largest CO2 transportation systems.

Wolf Midstream joined the project in 2018 as the pipeline’s owner and operator.

Completed in 2020, the groundbreaking $1.2 billion project — supported by the governments of Canada and Alberta — connects carbon captured at industrial sites near Edmonton to the Clive facility.

“With CO2 we’re able to revitalize some of these fields, continue to produce some of the resource that was left behind and permanently store CO2 emissions,” Paton said.

An oversized pipeline on purpose

Each year, about 1.6 million tonnes of CO2 captured at the NWR Sturgeon Refinery and Nutrien Redwater fertilizer facility near Fort Saskatchewan travels down the trunk line to Clive.

In a unique twist, that is only about 10 per cent of the pipeline’s available space. The project partners intentionally built it with room to grow.

“We have a lot of excess capacity. The vision behind the pipe was, let’s remove barriers for the future,” Kupchenko said.

The Alberta government-supported goal was to expand CCS in the province, said James Fann, CEO of the Regina-based International CCS Knowledge Centre.

“They did it on purpose. The size of the infrastructure project creates the opportunity for other emitters to build capture projects along the way,” he said.

CO2 captured at the Sturgeon Refinery near Edmonton is transported by the Alberta Carbon Trunk Line to the Clive project. Photo courtesy North West Redwater Partnership

Extending the value of aging assets

Building more CCUS projects like Clive that incorporate enhanced oil recovery (EOR) is a model for extending the economic value of aging oil and gas fields in Alberta, Kupchenko said.

“EOR can be thought of as redeveloping real estate,” he said.

“Take an inner-city lot with a 700-square-foot house on it. The bad thing is there’s a 100-year-old house that has to be torn down. But the great thing is there’s a road to it. There’s power to it, there’s a sewer connection, there’s water, there’s all the things.

“That’s what this is. We’re redeveloping a field that was discovered 70 years ago and has at least 30 more years of life.”

The 180 existing wellbores are also all assets, Kupchenko said.

“They may not all be producing oil or injecting CO2, but every one of them is used. They are our eyes into the reservoir.”

CO2 injection well at the Clive carbon capture, utilization and storage project. Photo for the Canadian Energy Centre

Alberta’s ‘beautiful’ CCUS geology

The existing wells are an important part of measurement, monitoring and verification (MMV) at Clive.

The Alberta Energy Regulator requires CCUS projects to implement a comprehensive MMV program to assess storage performance and demonstrate the long-term safety and security of CO₂.

Katherine Romanak, a subsurface CCUS specialist at the University of Texas at Austin, said that her nearly 20 years of global research indicate the process is safe.

“There’s never been a leak of CO2 from a storage site,” she said.

Alberta’s geology is particularly suitable for CCUS, with permanent storage potential estimated at more than 100 billion tonnes.

“The geology is beautiful,” Romanak said.

“It’s the thickest reservoir rocks you’ve ever seen. It’s really good injectivity, porosity and permeability, and the confining layers are crazy thick.”

CO2-EOR gaining prominence

The extra capacity on the ACTL pipeline offers a key opportunity to capitalize on storage potential while addressing aging oil and gas fields, according to the Alberta government’s Mature Asset Strategy, released earlier this year.

The report says expanding CCUS to EOR could attract investment, cut emissions and encourage producers to reinvest in existing properties — instead of abandoning them.

However, this opportunity is limited by federal policy.

Ottawa’s CCUS Investment Tax Credit, which became available in June 2024, does not apply to EOR projects.

“Often people will equate EOR with a project that doesn’t store CO2 permanently,” Kupchenko said.

“We like to always make sure that people understand that every ton of CO2 that enters this project is permanently sequestered. And we take great effort into storing that CO2.”

The International Energy Forum — representing energy ministers from nearly 70 countries including Canada, the U.S., China, India, Norway, and Saudi Arabia — says CO₂-based EOR is gaining prominence as a carbon sequestration tool.

The technology can “transform a traditional oil recovery method into a key pillar of energy security and climate strategy,” according to a June 2025 IEF report.

Tapping into more opportunity

In Central Alberta, Enhance Energy is advancing a new permanent CO2 storage project called Origins that is designed to revitalize additional aging oil and gas fields while reducing emissions, using the ACTL pipeline.

“Origins is a hub that’s going to enable larger scale EOR development,” Kupchenko said.

“There’s at least 10 times more oil in place in this area.”

Meanwhile, Wolf Midstream is extending the pipeline further into the Edmonton region to transport more CO2 captured from additional industrial facilities.

-

Business2 days ago

Business2 days agoOttawa Funded the China Ferry Deal—Then Pretended to Oppose It

-

COVID-192 days ago

COVID-192 days agoNew Peer-Reviewed Study Affirms COVID Vaccines Reduce Fertility

-

MAiD2 days ago

MAiD2 days agoCanada’s euthanasia regime is not health care, but a death machine for the unwanted

-

Business1 day ago

Business1 day agoWorld Economic Forum Aims to Repair Relations with Schwab

-

Alberta2 days ago

Alberta2 days agoThe permanent CO2 storage site at the end of the Alberta Carbon Trunk Line is just getting started

-

Alberta2 days ago

Alberta2 days agoAlberta’s government is investing $5 million to help launch the world’s first direct air capture centre at Innisfail

-

Business2 days ago

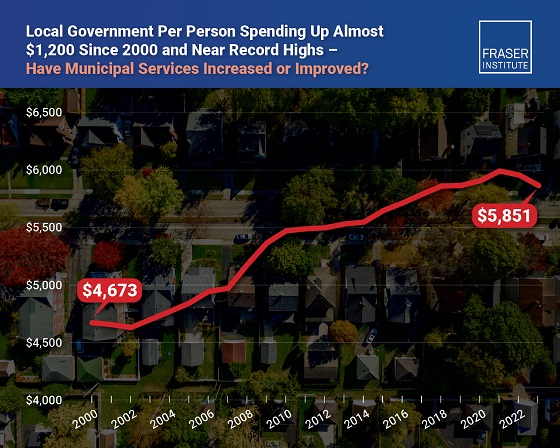

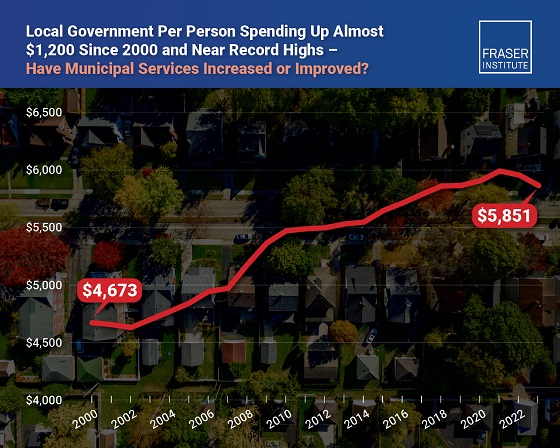

Business2 days agoMunicipal government per-person spending in Canada hit near record levels

-

Business2 days ago

Business2 days agoA new federal bureaucracy will not deliver the affordable housing Canadians need