Alberta

NOVA Chemicals partnership looking to solve massive problem of plastics waste!

NOVA Chemicals and Enerkem Collaborate to Close the Loop on Plastics Recycling

Research Seeks New Way to Reduce Waste to Landfill and Drive Zero Plastic Waste

Two Canadian companies will collaborate on innovative technology to close the loop on recycling and drive a plastics circular economy. NOVA Chemicals Corporation (“NOVA Chemicals”), a leading producer of chemicals and plastic resins, and Enerkem Inc. (“Enerkem”), a world-leading waste to renewable fuels and chemicals producer, have entered into a joint development agreement to explore turning non-recyclable and non-compostable municipal waste into ethylene, a basic building block of plastics.

Working together, the companies will research advanced recycling technology to transform hard-to-recycle municipal waste, including items such as plastics, household waste, and construction materials, into ethylene at full commercial scale. Ethylene, produced from waste, would advance a plastics circular economy and help meet consumer brand goals for recycled content in packaging.

Advanced recycling technologies are a necessary component of moving to zero plastic waste by creating valuable new feedstocks from post-use plastics that cannot be easily mechanically recycled. The quality of polymers produced with advanced recycling products is indistinguishable from those made from 100 percent virgin, fossil-based feedstocks.

“We are excited to work with Enerkem to create innovative, sustainable solutions for a plastics circular economy,” said Todd Karran, president and CEO, NOVA Chemicals. “Our R&D teams will collaborate to develop game changing technology to push the boundaries for recycling waste to create new feedstocks and bring value to the environment, economy and society.”

Enerkem is the first company in the world to produce renewable methanol and ethanol from non-recyclable, non-compostable municipal solid waste at full commercial scale. Its current technologies replace the use of fossil sources like petroleum and natural gas to produce sustainable transportation fuels and chemicals that are used in a broad range of everyday products.

“We are delighted to team up with NOVA Chemicals to collaborate on new technology for waste-to-ethylene feedstock to solve one of the world’s most pressing environmental issues,” said Dominique Boies, CEO and CFO, Enerkem. “This strategic partnership will allow us to explore the development of new products and expand our offering in pursuit of the circular economy.”

Peter Nieuwenhuizen, Enerkem’s Vice President of Technology Strategy & Deployment, added “With over 20 years of technology development, we have built a robust gasification platform to turn waste and biomass into fuels and chemicals with high carbon efficiency. Enerkem’s technology has the scale and versatility to supply raw materials for the circular and decarbonized chemical industry that is being created now. Not just for plastics but also for many other chemical ingredients that are vital for everyday life.”

NOVA Chemicals is committed to enabling 100 percent of plastics packaging is recyclable or recoverable by 2030; and 100 percent of plastics packaging is re-used, recycled or recovered by 2040. “This research is one of the ways NOVA Chemicals is innovating to recapture the value of plastic products and create a world free of plastic waste,” said Karran. “Working together, we can shape a world that is better tomorrow than it is today,” he added.

About NOVA Chemicals Corporation

NOVA Chemicals develops and manufactures chemicals and plastic resins that make everyday life healthier, easier and safer. Our employees work to ensure health, safety, security and environmental stewardship through our commitment to Sustainability and Responsible Care®. NOVA Chemicals, headquartered in Calgary, Alberta, Canada, is wholly-owned ultimately by Mubadala Investment Company of the Emirate of Abu Dhabi, United Arab Emirates.

Visit NOVA Chemicals on the Internet at www.novachem.com.

About Enerkem

Enerkem produces advanced biofuels and renewable chemicals from biomass and residual material. Its disruptive proprietary technology converts non-recyclable, non-compostable solid waste into methanol, ethanol and other widely used chemicals. Headquartered in Montréal, Québec, Canada, Enerkem operates a full-scale commercial facility in Alberta as well as an innovation centre in Québec. Enerkem’s facilities are built as prefabricated systems based on modular manufacturing infrastructure that can be deployed globally. Enerkem’s technology is a prime example of how a true circular economy can be achieved by diversifying the energy mix and by making everyday products greener while offering a smart, sustainable alternative to landfilling and incineration.

Agriculture

Lacombe meat processor scores $1.2 million dollar provincial tax credit to help expansion

Alberta’s government continues to attract investment and grow the provincial economy.

The province’s inviting and tax-friendly business environment, and abundant agricultural resources, make it one of North America’s best places to do business. In addition, the Agri-Processing Investment Tax Credit helps attract investment that will further diversify Alberta’s agriculture industry.

Beretta Farms is the most recent company to qualify for the tax credit by expanding its existing facility with the potential to significantly increase production capacity. It invested more than $10.9 million in the project that is expected to increase the plant’s processing capacity from 29,583 to 44,688 head of cattle per year. Eleven new employees were hired after the expansion and the company plans to hire ten more. Through the Agri-Processing Investment Tax Credit, Alberta’s government has issued Beretta Farms a tax credit of $1,228,735.

“The Agri-Processing Investment Tax Credit is building on Alberta’s existing competitive advantages for agri-food companies and the primary producers that supply them. This facility expansion will allow Beretta Farms to increase production capacity, which means more Alberta beef across the country, and around the world.”

“This expansion by Beretta Farms is great news for Lacombe and central Alberta. It not only supports local job creation and economic growth but also strengthens Alberta’s global reputation for producing high-quality meat products. I’m proud to see our government supporting agricultural innovation and investment right here in our community.”

The tax credit provides a 12 per cent non-refundable, non-transferable tax credit when businesses invest $10 million or more in a project to build or expand a value-added agri-processing facility in Alberta. The program is open to any food manufacturers and bio processors that add value to commodities like grains or meat or turn agricultural byproducts into new consumer or industrial goods.

Beretta Farms’ facility in Lacombe is a federally registered, European Union-approved harvesting and meat processing facility specializing in the slaughter, processing, packaging and distribution of Canadian and United States cattle and bison meat products to 87 countries worldwide.

“Our recent plant expansion project at our facility in Lacombe has allowed us to increase our processing capacities and add more job opportunities in the central Alberta area. With the support and recognition from the Government of Alberta’s tax credit program, we feel we are in a better position to continue our success and have the confidence to grow our meat brands into the future.”

Alberta’s agri-processing sector is the second-largest manufacturing industry in the province and meat processing plays an important role in the sector, generating millions in annual economic impact and creating thousands of jobs. Alberta continues to be an attractive place for agricultural investment due to its agricultural resources, one of the lowest tax rates in North America, a business-friendly environment and a robust transportation network to connect with international markets.

Quick facts

- Since 2023, there are 16 applicants to the Agri-Processing Investment Tax Credit for projects worth about $1.6 billion total in new investment in Alberta’s agri-processing sector.

- To date, 13 projects have received conditional approval under the program.

- Each applicant must submit progress reports, then apply for a tax credit certificate when the project is complete.

- Beretta Farms has expanded the Lacombe facility by 10,000 square feet to include new warehousing, cooler space and an office building.

- This project has the potential to increase production capacity by 50 per cent, thereby facilitating entry into more European markets.

Related information

Alberta

Alberta Next: Alberta Pension Plan

From Premier Danielle Smith and Alberta.ca/Next

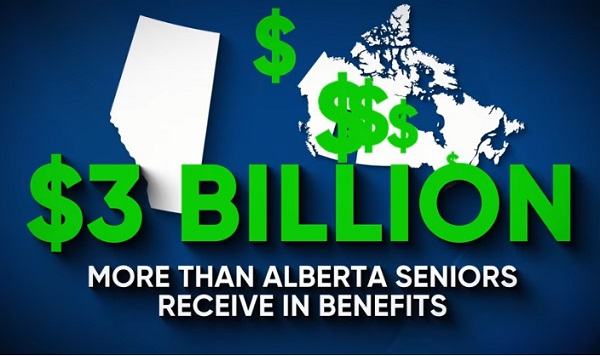

Let’s talk about an Alberta Pension Plan for a minute.

With our young Alberta workforce paying billions more into the CPP each year than our seniors get back in benefits, it’s time to ask whether we stay with the status quo or create our own Alberta Pension Plan that would guarantee as good or better benefits for seniors and lower premiums for workers.

I want to hear your perspective on this idea and please check out the video. Get the facts. Join the conversation.

Visit Alberta.ca/next

-

Agriculture2 days ago

Agriculture2 days agoCanada’s supply management system is failing consumers

-

Economy2 days ago

Economy2 days agoTrump opens door to Iranian oil exports

-

Alberta1 day ago

Alberta1 day agoCOVID mandates protester in Canada released on bail after over 2 years in jail

-

Business1 day ago

Business1 day agoCanada’s loyalty to globalism is bleeding our economy dry

-

armed forces23 hours ago

armed forces23 hours agoCanada’s Military Can’t Be Fixed With Cash Alone

-

Crime1 day ago

Crime1 day agoProject Sleeping Giant: Inside the Chinese Mercantile Machine Linking Beijing’s Underground Banks and the Sinaloa Cartel

-

Alberta1 day ago

Alberta1 day agoAlberta uncorks new rules for liquor and cannabis

-

Business1 day ago

Business1 day agoCarney’s spending makes Trudeau look like a cheapskate