Environment

Emmy Award Winning Journalist reveals how “fact checkers” punish ‘tone’ even when the facts check out

When one of media’s most successful journalists is constantly punished by Facebook Fact Checkers it makes for a compelling story all on it’s own. Does a 19 time Emmy Award Winning Journalist not check his facts? Well… turns out the facts aren’t the problem. Enjoy some more revealing insight from John Stossel.

From StosselTV

Before Facebook censored it, my video, “Are We Doomed”, got more 24 million views. You can watch it here: https://www.youtube.com/watch?v=b8JZo… Now Facebook won’t show it to many people — not even to my subscribers. Facebook’s also punishing Stossel TV by showing our other videos less. All because Facebook foolishly gave Emmanuel Vincent, a recent PhD graduate from France, the power to censor. Vincent assembled a group of like-minded scientists into a group called Climate Feedback climatefeedback.org that declared parts of my video “misleading,” or “partially false.” What facts did the “fact-checkers” correct? NONE! There was not a single hard fact that in the video that was wrong. We address the censor’s claims here, listing our sources: https://www.johnstossel.com/climate-f… I asked one Vincent “reviewer,” the only one willing to be interviewed, why I deserve censorship even though our facts were correct.

After 40+ years of reporting, I now understand the importance of limited government and personal freedom. Libertarian journalist John Stossel is a zealous advocate of free markets, a syndicated columnist and Fox News contributor. Prior to joining Fox, John co-anchored ABC’s primetime newsmagazine show, 20/20. Stossel’s economic programs have been adapted into teaching kits by a non-profit organization, “Stossel in the Classroom.” High school teachers in American public schools now use the videos to help educate their students on economics and economic freedom. They are seen by more than 12 million students every year. Stossel has received 19 Emmy Awards and has been honored five times for excellence in consumer reporting by the National Press Club. Other honors include the George Polk Award for Outstanding Local Reporting and the George Foster Peabody Award.

Energy

B.C. Residents File Competition Bureau Complaint Against David Suzuki Foundation for Use of False Imagery in Anti-Energy Campaigns

From Energy Now and The Canadian Newswire

A group of eight residents of Northeast British Columbia have filed a formal application for inquiry with Canada’s Competition Bureau, calling for an investigation into the David Suzuki Foundation’s (the Foundation) use of false and misleading imagery in its anti-energy campaigns.

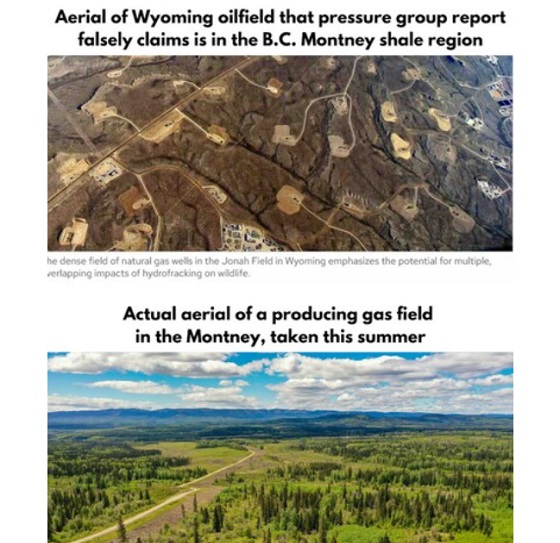

The complaint alleges that the Foundation has repeatedly used a two-decade-old aerial photograph of Wyoming gas wells to falsely depict modern natural gas development in B.C.’s Montney Formation. This area produces roughly half of Canada’s natural gas.

Key Facts:

- The misleading image has been used on the Foundation’s website, social media pages, reports and donation appeals.

- The Foundation has acknowledged the image’s true source (Wyoming) in some contexts but has continued to use it to represent B.C. development.

- The residents claim this materially misleads donors and the public, violating Section 74.01(1) of the Competition Act.

- The complaint is filed under Sections 9 and 10 of the Act, asking the Bureau to investigate and impose remedies including ceasing the conduct, publishing corrective notices, and returning proceeds.

Quote from Deena Del Giusto, Spokesperson:

“This is about fairness and truth. The people of Northeast B.C. are proud of the work they do to produce energy for Canada and the world. They deserve honest debate, not scare tactics and misleading imagery used to raise millions in donations. We’re asking the Competition Bureau to hold the David Suzuki Foundation to the same standard businesses face: tell the truth.”

Background:

Natural gas development in the Montney Formation supports thousands of jobs and fuels economic activity across the region. Accurate public information is vital to informed debate, especially as many Canadians live far from production sites.

SOURCE Deena Del Giusto

Canadian Energy Centre

Alberta oil sands legacy tailings down 40 per cent since 2015

Wapisiw Lookout, reclaimed site of the oil sands industry’s first tailings pond, which started in 1967. The area was restored to a solid surface in 2010 and now functions as a 220-acre watershed. Photo courtesy Suncor Energy

From the Canadian Energy Centre

By CEC Research

Mines demonstrate significant strides through technological innovation

Tailings are a byproduct of mining operations around the world.

In Alberta’s oil sands, tailings are a fluid mixture of water, sand, silt, clay and residual bitumen generated during the extraction process.

Engineered basins or “tailings ponds” store the material and help oil sands mining projects recycle water, reducing the amount withdrawn from the Athabasca River.

In 2023, 79 per cent of the water used for oil sands mining was recycled, according to the latest data from the Alberta Energy Regulator (AER).

Decades of operations, rising production and federal regulations prohibiting the release of process-affected water have contributed to a significant accumulation of oil sands fluid tailings.

The Mining Association of Canada describes that:

“Like many other industrial processes, the oil sands mining process requires water.

However, while many other types of mines in Canada like copper, nickel, gold, iron ore and diamond mines are allowed to release water (effluent) to an aquatic environment provided that it meets stringent regulatory requirements, there are no such regulations for oil sands mines.

Instead, these mines have had to retain most of the water used in their processes, and significant amounts of accumulated precipitation, since the mines began operating.”

Despite this ongoing challenge, oil sands mining operators have made significant strides in reducing fluid tailings through technological innovation.

This is demonstrated by reductions in “legacy fluid tailings” since 2015.

Legacy Fluid Tailings vs. New Fluid Tailings

As part of implementing the Tailings Management Framework introduced in March 2015, the AER released Directive 085: Fluid Tailings Management for Oil Sands Mining Projects in July 2016.

Directive 085 introduced new criteria for the measurement and closure of “legacy fluid tailings” separate from those applied to “new fluid tailings.”

Legacy fluid tailings are defined as those deposited in storage before January 1, 2015, while new fluid tailings are those deposited in storage after January 1, 2015.

The new rules specified that new fluid tailings must be ready to reclaim ten years after the end of a mine’s life, while legacy fluid tailings must be ready to reclaim by the end of a mine’s life.

Total Oil Sands Legacy Fluid Tailings

Alberta’s oil sands mining sector decreased total legacy fluid tailings by approximately 40 per cent between 2015 and 2024, according to the latest company reporting to the AER.

Total legacy fluid tailings in 2024 were approximately 623 million cubic metres, down from about one billion cubic metres in 2015.

The reductions are led by the sector’s longest-running projects: Suncor Energy’s Base Mine (opened in 1967), Syncrude’s Mildred Lake Mine (opened in 1978), and Syncrude’s Aurora North Mine (opened in 2001). All are now operated by Suncor Energy.

The Horizon Mine, operated by Canadian Natural Resources (opened in 2009) also reports a significant reduction in legacy fluid tailings.

The Muskeg River Mine (opened in 2002) and Jackpine Mine (opened in 2010) had modest changes in legacy fluid tailings over the period. Both are now operated by Canadian Natural Resources.

Imperial Oil’s Kearl Mine (opened in 2013) and Suncor Energy’s Fort Hills Mine (opened in 2018) have no reported legacy fluid tailings.

Suncor Energy Base Mine

Between 2015 and 2024, Suncor Energy’s Base Mine reduced legacy fluid tailings by approximately 98 per cent, from 293 million cubic metres to 6 million cubic metres.

Syncrude Mildred Lake Mine

Between 2015 and 2024, Syncrude’s Mildred Lake Mine reduced legacy fluid tailings by approximately 15 per cent, from 457 million cubic metres to 389 million cubic metres.

Syncrude Aurora North Mine

Between 2015 and 2024, Syncrude’s Aurora North Mine reduced legacy fluid tailings by approximately 25 per cent, from 102 million cubic metres to 77 million cubic metres.

Canadian Natural Resources Horizon Mine

Between 2015 and 2024, Canadian Natural Resources’ Horizon Mine reduced legacy fluid tailings by approximately 36 per cent, from 66 million cubic metres to 42 million cubic metres.

Total Oil Sands Fluid Tailings

Reducing legacy fluid tailings has helped slow the overall growth of fluid tailings across the oil sands sector.

Without efforts to reduce legacy fluid tailings, the total oil sands fluid tailings footprint today would be approximately 1.6 billion cubic metres.

The current fluid tailings volume stands at approximately 1.2 billion cubic metres, up from roughly 1.1 billion in 2015.

The unaltered reproduction of this content is free of charge with attribution to the Canadian Energy Centre.

-

Agriculture2 days ago

Agriculture2 days agoCanada’s supply management system is failing consumers

-

Alberta1 day ago

Alberta1 day agoCOVID mandates protester in Canada released on bail after over 2 years in jail

-

Crime1 day ago

Crime1 day agoProject Sleeping Giant: Inside the Chinese Mercantile Machine Linking Beijing’s Underground Banks and the Sinaloa Cartel

-

Alberta1 day ago

Alberta1 day agoAlberta uncorks new rules for liquor and cannabis

-

Business1 day ago

Business1 day agoCanada’s loyalty to globalism is bleeding our economy dry

-

armed forces24 hours ago

armed forces24 hours agoCanada’s Military Can’t Be Fixed With Cash Alone

-

International1 day ago

International1 day agoTrump transportation secretary tells governors to remove ‘rainbow crosswalks’

-

Business1 day ago

Business1 day agoCarney’s spending makes Trudeau look like a cheapskate