By Geoff Russ

Compared to last December, Canadians are paying far more attention.

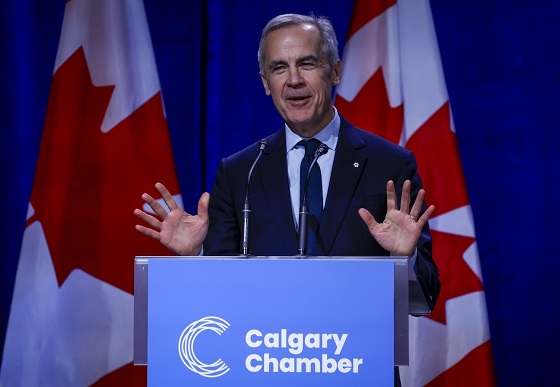

Canada’s energy conversation has changed in a year, not by becoming gentler, but by becoming real. In late 2024, pipelines were still treated as symbols, and most people tuned out. By December 2025, Canadians are arguing about tolls, tariffs, tanker law, carbon pricing, and Indigenous equity in the same breath, because those details now ultimately decide what gets built and what stays in the binder. Prime Minister Mark Carney has gone from a green bureaucrat to an ostensible backer of another pipeline from Alberta to the West Coast.

From hypothetical to live instrument

The pivot began when the Trans Mountain expansion started operating in May 2024, tripling capacity from Alberta to the B.C. coast. The project’s C$34 billion price tag, and the question of who absorbs the overrun, forced a more adult debate than the old slogans ever allowed. With more barrels moving and new Asian cargoes becoming routine, the line stopped being hypothetical and became a live economic instrument, complete with uncomfortable arithmetic about costs, revenues, and taxpayer exposure.

The American election cycle then poured gasoline on the discussion. Talk in Washington about resurrecting Keystone XL, alongside President-elect Donald Trump’s threats of 25 percent tariffs, reminded Canadians how quickly market access can be turned into leverage.

In that context, Trans Mountain is being discussed not just as infrastructure, but as an emergency outlet if U.S. refiners start pricing in new levies.

The world keeps building

Against that backdrop, the world kept building. Global pipeline planning has not paused for Canadian anxieties, with more than 233,000 kilometres of large diameter oil and gas lines announced or advancing for 2024 to 2030. The claim that blocking Canadian projects keeps fossil fuels in the ground sounds thinner when other jurisdictions are plainly racing ahead.

The biggest shift, though, is domestic. Ottawa and Alberta signed a memorandum of understanding in late November 2025 that sketches conditions for a potential new oil pipeline to the West Coast, alongside a strengthened industrial carbon price and a Pathways Alliance carbon capture requirement. One Financial Post column argued the northwest coast fight may be a diversion, because cheaper capacity additions are on the table. Another argued the MOU is effectively a set of investment killers, because tanker ban changes, Indigenous co ownership, B.C. engagement, and CCUS preconditions create multiple points of failure.

This is where Margareta Dovgal deserves credit. Writing about the Commons vote where Conservatives tabled a motion echoing the Liberals’ own MOU language, she captured the new mood. Canadians are no longer impressed by politicians who talk like builders and vote like blockers. Symbolic yeses and procedural noes are now obvious, and voters are keeping score.

Skills for a new era

The same sharper attention is landing on carbon capture, once a technocratic sidebar. Under the MOU, a new bitumen corridor is tied to Pathways Alliance scale carbon management, and that linkage is already shaping labour planning. A Calgary based training initiative backed by federal funding aims to prepare more than 1,000 workers for carbon capture and storage roles, a sign that contested policy is producing concrete demand for skills.

British Columbia is no longer watching from the bleachers. It flared again at Carney’s December 18 virtual meeting, after Environment Minister Steven Guilbeault resigned from cabinet over it. Premier David Eby has attacked the Alberta Ottawa agreement as unacceptable, and Prime Minister Mark Carney has been forced into talks with premiers amid trade uncertainty. Polling suggests the public mood is shifting, too, with a slim majority of Canadians, and of British Columbians, saying they would support a new Alberta to West Coast pipeline even if the B.C. government opposed it, and similar support for lifting the tanker ban.

None of this guarantees a new line, or even an expanded one. But compared with last year’s tired trench warfare, the argument now has stakes, participants, and facts. Canadians have woken up to the reality that energy policy is not a culture war accessory. It is industrial policy, trade policy, and national unity policy, all at once.

Resource Works News

Related