Also Interesting

Actuators in Industrial Automation: How They Improve Efficiency

In the quest for enhanced productivity and reduced operational costs, many industries face challenges in optimizing their automation systems. Integrating advanced technologies, such as actuators, alleviates these issues by automating processes and minimizing manual intervention. Leveraging the capabilities of an actuator allows businesses to streamline operations and achieve higher efficiency.

Industrial automation continues to evolve, with a focus on precision and reliability. As of 2025, advancements in automation technologies are projected to increase productivity by up to 30% in various sectors, according to the International Federation of Robotics report. This growth is attributed to the strategic use of components like the actuator, pivotal in enhancing operational efficiency.

Actuators: What are They?

Actuators are mechanical devices that convert energy into motion and enable precise control over various industrial processes. They are categorized into:

Electric

Hydraulic

Linear

Each type offers unique advantages (e.g., precision, force, speed) for different applications. Understanding what actuators are and how they work is crucial for application in industrial settings.

The question “What are actuators?” is often followed by “What is the work of an actuator?” These devices perform tasks that require movement or force (e.g., opening valves, moving parts in machinery, or adjusting positions in assembly lines). They are integral to systems requiring precise control, making them a cornerstone of modern automation.

The Role of Actuators in Industrial Automation

Actuators are the backbone of industrial automation, enabling precise control and integration across systems. Their ability to convert energy into motion makes them indispensable for optimizing processes, reducing costs, and improving productivity.

In control systems, they work with sensors to enable real-time adjustments. For example, in food processing plants, electric motors adjust conveyor speeds, ensuring consistent packaging and reducing waste. It minimizes downtime and saves businesses time and money.

In robotics, devices like the actuator arm deliver high precision. In automotive assembly lines, linear drives allow robotic arms to weld or paint with millimeter accuracy, reducing rework and enhancing product quality.

Beyond robotics, these motors streamline machinery operations. In the oil and gas industry, hydraulic motors control pipeline valves, eliminating manual intervention in hazardous environments and improving safety.

How Actuators Improve Operational Efficiency

Here is how actuators enhance industrial operation:

They offer precise control over movements, essential in applications requiring high accuracy (e.g., manufacturing, robotics). It reduces errors and improves product quality. For example, in CNC machining, linear actuators ensure cuts are made with exactness, resulting in parts that meet precise specifications.

They speed up production cycles, allowing for higher output in less time. It is beneficial in assembly lines where actuator assembly and actuator adapter components are used to streamline processes. In automotive manufacturing, they can quickly position and secure parts, reducing assembly time.

They minimize the need for human intervention, reducing the risk of errors and accidents. It improves safety and increases productivity by allowing workers to focus on more complex tasks.

In environments where repetitive tasks are common, motors automate these processes, freeing up personnel for strategic roles.

Applications of Actuators in Various Industries

Actuators are used across different industries to enhance efficiency and productivity.

Manufacturing. Linear drives are used in machinery to ensure precise movements and consistent product quality. They are integral in assembly lines, where they automate tasks such as positioning and lifting components. For instance, in electronics manufacturing, actuators precisely place components on circuit boards, ensuring each product meets quality standards.

Oil and gas. Here, hydraulic motors are used for valve control due to their high force capabilities, necessary for handling heavy loads.

Food processing. In this niche, electric motors are preferred for their cleanliness and low maintenance, ensuring production lines remain hygienic and efficient. They are used in machinery requiring precise control (e.g., filling and packaging systems).

How to Choose the Right Industrial Actuator

Evaluate several factors for optimal compatibility with your applications:

Determine whether your application demands linear, rotary, or oscillatory motion. For example, linear motors are ideal for tasks requiring straight-line movement, such as positioning components in manufacturing lines.

Assess the load capacity and force requirements of your application. Heavy-duty applications, like those in the oil and gas sector, often require hydraulic actuators due to their high force capabilities.

Evaluate the operating environment, considering factors such as temperature, humidity, dust, and corrosive conditions. Ensure the actuator’s materials and design are suitable for these conditions by checking IP ratings, temperature limits, and corrosion resistance.

Ensure the motor is compatible with existing control systems. It includes considering manual, mechanical, electrical, or computer-based control options to ensure integration.

Consider safety factors (e.g., emergency stop mechanisms and fail-safe designs), especially in critical applications like vehicle automation.

Actuators are essential in industrial automation, delivering precision, speed, and efficiency to optimize operations across sectors. Integrating the right motors will allow businesses to reduce costs, enhance productivity, and maintain a competitive edge in an automated landscape.

Also Interesting

How Classic Slots Features Are Evolving

Slot machines have remained popular with players for over a century, with the same simple mechanism still being used to create winning spins across a series of reels. Yet, these games have evolved somewhat in recent years, as some of the classic features have been updated to introduce new gameplay mechanics and features.

Free Spins and Bonus Rounds

The first slot machine was created in the 1890s, with bonus rounds added by the 1930s. The introduction of electromechanical devices like Money Honey from Bally in the 1960s introduced programmable bonus rounds, replacing manually-triggered features and expanding gameplay variety. This has been followed by a huge variety of rounds, where players get free spins, collect symbols, or choose mystery objects, among others.

Modern online slots include a wide variety of bonus rounds, such as those that can be seen in the Hold & Win titles. These games typically give players at least one free re-spin, with special symbols locked into place.

Progressive Jackpots

The earliest slot machine to offer a progressive jackpot was Megabucks by International Game Technology in 1986. This mechanism allowed players to try and win a jackpot that climbed every time someone played the slot, with the jackpot finally paying out on a random spin. It greatly increases the available prizes and has remained a popular feature among slot

enthusiasts.

Online progressive slot games like Thunderstruck II Maple Moolah, Gladiator Jackpot, and Buffalo Blitz Megaways all showcase the sheer variety on offer in the contemporary landscape, with each having unique jackpot mechanisms. The Maple Moolah range of slots by Games Global takes popular slots and includes a jackpot seed of $1 million that increases with continued play. Most progressive jackpots are still awarded randomly, but some include a bonus game that triggers a payout.

Multipliers Can Be Added in a Number of Ways

Win multipliers have been a big part of the slots world since the first electromechanical machines were created in the middle of the 20th century. At first, this was a simple but effective way of increasing wins by 2x or 3x when the right symbols landed, meaning that players had the potential to receive payouts beyond standard paytable values. But they now get used in increasingly sophisticated ways that add more than just bigger wins.

Increasing multipliers are used to give an ever-bigger boost to winning spins. This type of multiplier can grow with each winning spin on some slots, while others increase with each spin made during the free spins round. An interesting twist sees multipliers earned by collecting special symbols, which accumulate multiplier levels through a meter-based system.

The way that these slot features have evolved is an indicator of the way that the online gaming industry has expanded significantly in recent years. We can expect to see more new features added in the future, while the traditional features we’ve looked at here will likely continue to evolve as new design elements are introduced.

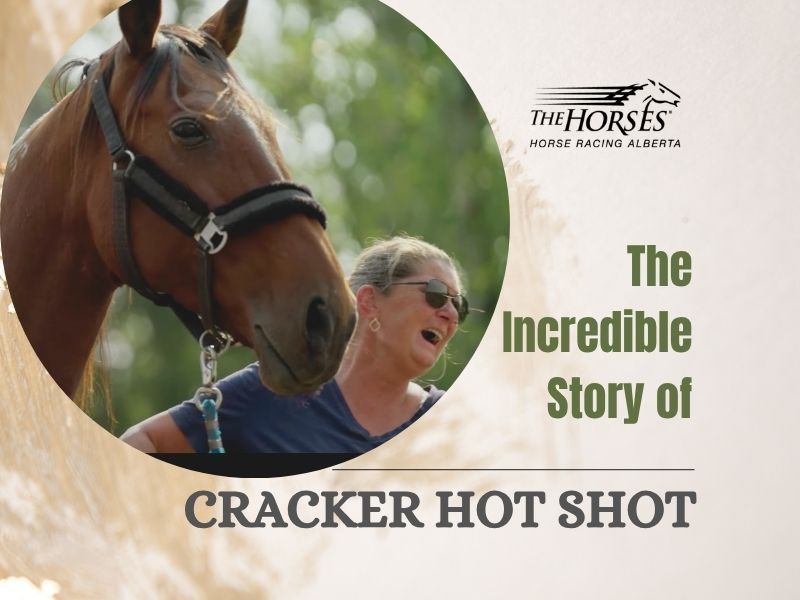

Alberta

From Underdog to Top Broodmare

WATCH From Underdog to Top Broodmare (video)

Executive Producers Jeff Robillard (Horse Racing Alberta) and Mike Little (Shinelight Entertainment)

What began as an underdog story became a legacy of excellence. Crackers Hot Shot didn’t just race — she paved the way for future generations, and in doing so became one of the most influential producers the province has known.

The extraordinary journey of Crackers Hot Shot — once overlooked, now revered — stands as one of Alberta’s finest success stories in harness racing and breeding.

Born in humble circumstances and initially considered rough around the edges, Crackers Hot Shot overcame long odds to carve out a career that would forever impact the province’s racing industry. From a “wild, unhandled filly” to Alberta’s “Horse of the Year” in 2013, to producing foals who carry her spirit and fortitude into future generations.

Her influence ripples through Alberta’s racing and breeding landscape: from how young stock are prepared, to the aspirations of local breeders who now look to “the mare that did it” as proof that world-class talent can emerge from Alberta’s paddocks.

“Crackers Hot Shot, she had a tough start. She wasn’t much to look at when we first got her” — Rod Starkewski

“Crackers Hot Shot was left on her own – Carl Archibald heard us talking, he said ‘I’ll go get her – I live by there’. I think it took him 3 days to dig her out of the snow. She was completely wild – then we just started working on her. She really needed some humans to work with her – and get to know that people are not scary.” — Jackie Starkewski

“Crackers Hot Shot would be one of the top broodmares in Albeta percentage wise if nothing else. Her foals hit the track – they’re looking for the winners circle every time.” — Connie Kolthammer

Visit thehorses.com to learn more about Alberta’s Horse Racing industry.

-

Energy2 days ago

Energy2 days agoEby should put up, shut up, or pay up

-

Business2 days ago

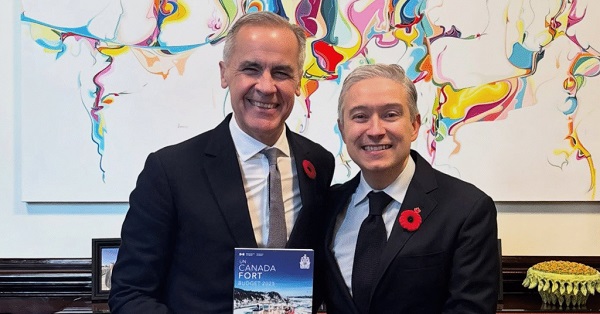

Business2 days agoPulling back the curtain on the Carney government’s first budget

-

Daily Caller2 days ago

Daily Caller2 days agoUS Eating Canada’s Lunch While Liberals Stall – Trump Admin Announces Record-Shattering Energy Report

-

Business2 days ago

Business2 days agoThe Liberal budget is a massive FAILURE: Former Liberal Cabinet Member Dan McTeague

-

Business1 day ago

Business1 day agoCarney’s budget spares tax status of Canadian churches, pro-life groups after backlash

-

COVID-191 day ago

COVID-191 day agoFreedom Convoy leader Tamara Lich to appeal her recent conviction

-

Justice1 day ago

Justice1 day agoCarney government lets Supreme Court decision stand despite outrage over child porn ruling

-

espionage20 hours ago

espionage20 hours agoU.S. Charges Three More Chinese Scholars in Wuhan Bio-Smuggling Case, Citing Pattern of Foreign Exploitation in American Research Labs