Canadian Energy Centre

AltaGas boosts Canada-Asia energy trade with new butane exports

From the Canadian Energy Centre

Demand for versatile fuels rising to power higher living standards

A deal to supply Asian customers with butane shipped from the coast of B.C. promises to expand Canada’s global energy footprint, underscoring untapped potential and the benefits of diversifying beyond the U.S. market.

Butane and propane are what’s known as liquid petroleum gases (LPGs).

Produced during natural gas processing and oil refining, these versatile energy products are in high demand for a wide range of uses including feedstock for plastics and synthetic rubber production, fuels for heating and cooking, and solvents in industrial applications.

“Demand remains strong going forward for the Asian markets as consumers continue to increase living standards and income levels and use more of the everyday items that we take for granted,” said Martin King, managing director of North America energy market analysis for Houston-based RBN Energy.

The new deal commits Calgary-based AltaGas to supply German chemical giant BASF with butane for chemical manufacturing and industrial use in Asian markets.

Butane and propane from Alberta can be shipped by rail to reach terminals on the West Coast, including the AltaGas Ridley Island Energy Export Facility that is under construction near Prince Rupert.

Known as REEF, it is an expansion of the company’s LPG export operations that is scheduled to start operating in 2027. AltaGas opened Canada’s first marine propane export terminal on Ridley Island in 2019.

BASF president of global procurement Matthias Dohrn said partnering with AltaGas secures “reliable and competitive access” to butane from Western Canada.

While details on the scope of the agreement were not released, King said AltaGas is already talking about expanding REEF capacity by 2030.

“I suspect that the expansion has a good chance of going ahead given that the demand for LPGs out of Asia has remained very robust,” he said.

Canada’s success in growing propane exports offers a model for butane’s potential.

According to the Canada Energy Regulator (CER), propane exports – most of which come from Alberta – have more than doubled over the past decade as the new B.C. terminal infrastructure came online.

As of June 2025, shipments to non-U.S. locations were nearly even with exports south of the border, CER reports.

According to the Canadian Propane Association (CPA), the largest customers after the U.S. are Japan, South Korea and Mexico.

Earlier this year, the CPA joined Alberta government officials, industry representatives and Indigenous leaders on a trade mission to Japan aimed at diversifying Canada’s energy exports.

“Canadian propane, with its lower carbon footprint, is uniquely positioned to support Japan’s decarbonization efforts,” said the CPA’s President and CEO Shannon Watt.

“By collaborating with Japan, we can demonstrate how Canadian propane meets the demand for sustainable energy solutions while enhancing energy security in a complex geopolitical landscape.”

Alberta

How Alberta is moving to speed up oil sands reclamation with mine water treatment

From the Canadian Energy Centre

New standards to build on rules already in place for other mining sectors

In what the former Chief of the Fort McKay First Nation calls “a critical step in the right direction,” the Alberta government is moving to accelerate reclamation of more than 1.3 trillion litres of water stored in oil sands tailings ponds.

On Sept. 5, the province announced it will expedite setting standards that allow for “mine water” to be treated and released into the environment, building on the rules that are already in place for other mining operations across Canada.

“We cannot ignore this challenge, we need to keep working together to find practical and effective solutions that protect Indigenous rights, people and the environment,” said Chief Jim Boucher, a member of Alberta’s Oil Sands Mine Water Steering Committee.

That committee is behind a suite of nine recommendations that Alberta is putting into action to improve mine water management and tailings pond reclamation.

The Mining Association of Canada (MAC) says decades of research give the industry confidence that mine water can be safely treated and released once regulations are in place.

But that will take the federal government moving faster too.

Both the federal and provincial governments play a role in potential regulations for the treatment and release of oil sands mine water.

“Alberta is proposing science-based parameters to ensure the safe return of treated water used in oil sands mining, just as other provincial governments do for their respective mining sectors,” MAC CEO Pierre Gratton said in a statement.

“We are hopeful that this will accelerate the development of federal regulations – which we requested almost 15 years ago – to be similarly advanced.”

Gratton said setting standards for safe mine water release could unlock “significant investments” in oil sands reclamation and water treatment.

What are tailings ponds?

Tailings are a byproduct of mining operations around the world.

Oil sands tailings ponds are engineered basins holding a mix of mine water, sand, silt, clay and residual bitumen generated during the extraction process. There are eight operating oil sands mines with tailings ponds in northern Alberta.

Recycling water held in these basins helps operators reduce the amount of fresh water withdrawn from the Athabasca River.

In 2023, 79 per cent of the water used for oil sands mining was recycled, according to the Alberta Energy Regulator.

What is oil sands mine water?

Oil sands mine water is water that comes into contact with the various stages of oil sands mining operations, including bitumen extraction and processing.

Tailings ponds in the oil sands also hold water from significant amounts of rain and snow collected in the decades since the first mines began operating.

While the oil sands mining sector has reduced the amount of fresh water it uses per barrel of oil produced by nearly one-third since 2013, the total volume of mine water in tailings storage has grown as production has increased.

What’s in oil sands mine water?

The constituents of oil sands mine water requiring treatment for safe release are both typical of water in other industrial processes and unique to the oil sands sector.

MAC says common materials are suspended solids like sand, silt and clay, as well as a range of metals. These can be treated by a wide range of proven technologies already in use in Canada and globally.

Unique to oil sands mine water are organic compounds such as naphthenic acids. According to MAC, operators have demonstrated and continue to invest in processes to treat these to levels safe for environmental release.

How does mine water impact reclamation?

At the end of an oil sands mine’s life, operators must remove all infrastructure and restore the land to features of a self-sustaining boreal forest similar to what was there before.

Addressing the challenge of tailings ponds and the mine water stored in them is critical to the overall success of oil sands mining reclamation.

Why is mine water release important?

MAC says the only way to remove mine water in tailings ponds is to treat it for safe release to the environment.

Strict regulations allow for this process across Canadian copper, nickel, gold, iron ore, and diamond mining operations. But it is prohibited in the oil sands.

The safe release of treated oil sands mine water into the environment can reduce the need to store it, minimize further land disturbance and help reclamation happen faster.

MAC says operators have shown they can treat mine water to safe release levels, using processes that include innovative technologies developed through Canada’s Oil Sands Innovation Alliance.

What is Alberta doing?

Alberta has accepted the Oil Sands Mine Water Steering Committee’s nine recommendations aimed at speeding up solutions for safe mine water release.

The province says the recommendations, developed with input from industry, technology providers, Indigenous communities and scientists, will now be evaluated to determine how they can be put into practice.

Canadian Energy Centre

Emissions cap will end Canada’s energy superpower dream

From the Canadian Energy Centre

By Will Gibson

Study finds legislation’s massive cost outweighs any environmental benefit

The negative economic impact of Canada’s proposed oil and gas emissions cap will be much larger than previously projected, warns a study by the Center for North American Prosperity and Security (CNAPS).

The report concluded that the cost of the emissions cap far exceeds any benefit from emissions reduction within Canada, and it could push global emissions higher instead of lower.

Based on findings this March by the Office of the Parliamentary Budget Officer (PBO), CNAPS pegs the cost of the cap to be up to $289,000 per tonne of reduced emissions.

That’s more than 3,600 times the cost of the $80-per-tonne federal carbon tax eliminated this spring.

The proposed cap has already chilled investment as Canada’s policymakers look to “nation-building” projects to strengthen the economy, said lead author Heather Exner-Pirot.

“Why would any proponent invest in Canada with this hanging over it? That’s why no other country is talking about an emissions cap on its energy sector,” said Exner-Pirot, director of energy, natural resources and environment at the Macdonald-Laurier Institute.

Federal policy has also stifled discussion of these issues, she said. Two of the CNAPS study’s co-authors withdrew their names based on legal advice related to the government’s controversial “anti-greenwashing” legislation.

“Legitimate debate should not be stifled in Canada on this or any government policy,” said Exner-Pirot.

“Canadians deserve open public dialogue, especially on policies of this economic magnitude.”

Carbon leakage

To better understand the impact of the cap, CNAPS researchers expanded the PBO’s estimates to reflect impacts beyond Canada’s borders.

“The problem is something called carbon leakage. We know that while some regions have reduced their emissions, other jurisdictions have increased their emissions,” said Exner-Pirot.

“Western Europe, for example, has de-industrialized but emissions in China are [going up like] a hockey stick, so all it’s done is move factories and plants from Europe to China along with the emissions.”

Similarly, the Canadian oil and gas production cut by the cap will be replaced in global markets by other producers, she said. There is no reason to assume capping oil and gas emissions in Canada will affect global demand.

The federal budget office assumed the legislation would reduce emissions by 7.1 million tonnes. CNAPS researchers applied that exclusively to Canada’s oil sands.

Here’s the catch: on average, oil sands crude is only about 1 to 3 percent more carbon-intensive than the average crude oil used globally (with some facilities emitting less than the global average).

So, instead of the cap reducing world emissions by 7.1 million tonnes, the real cut would be only 1 to 3 percent of that total, or about 71,000 to 213,000 tonnes worldwide.

In that case, using the PBO’s estimate of a $20.5 billion cost for the cap in 2032, the price of carbon is equivalent to $96,000 to $289,000 per tonne.

Economic pain with no environmental gain

Exner-Pirot said doing the same math with Canada’s “conventional” or non-oil sands production makes the situation “absurd.”

That’s because Canadian conventional oil and natural gas have lower emissions intensity than global averages. So reducing that production would actually increase global emissions, resulting in an infinite price per tonne of carbon.

“This proposal creates economic pain with no environmental gain,” said Samantha Dagres, spokesperson for the Montreal Economic Institute.

“By capping emissions here, you are signalling to investors that Canada isn’t interested in investment. Production will move to jurisdictions with poorer environmental standards as well as bad records on human rights.”

There’s growing awareness about the importance of the energy sector to Canada’s prosperity, she said.

“The public has shown a real appetite for Canada to become an energy superpower. That’s why a June poll found 73 per cent of Canadians, including 59 per cent in Quebec, support pipelines.”

Industries need Canadian energy

Dennis Darby, CEO of Canadian Manufacturers & Exporters (CME), warns the cap threatens Canada’s broader economic interests due to its outsized impact beyond the energy sector.

“Our industries run on Canadian energy. Canada should not unnecessarily hamstring itself relative to our competitors in the rest of the world,” said Darby.

CME represents firms responsible for over 80 per cent of Canada’s manufacturing output and 90 per cent of its exports.

Rather than the cap legislation, the Ottawa-based organization wants the federal government to offer incentives for sectors to reduce their emissions.

“We strongly believe in the carrot approach and see the market pushing our members to get cleaner,” said Darby.

-

Agriculture2 days ago

Agriculture2 days agoOttawa’s EV Gamble Just Cost Canola Farmers Billions

-

Business2 days ago

Business2 days agoHow the feds blew your money this week

-

Frontier Centre for Public Policy2 days ago

Frontier Centre for Public Policy2 days agoCharlie Kirk Fought A Progressive Ideology That Punishes Truth

-

Business2 days ago

Business2 days agoCanadian gov’t spending on DEI programs exceeds $1 billion since 2016

-

Censorship Industrial Complex2 days ago

Censorship Industrial Complex2 days agoMedia’s Psyop Against Climate Scientists

-

Crime2 days ago

Crime2 days agoCharlie Kirk’s Widow Says She Forgives Her Husband’s Assassin During Memorial

-

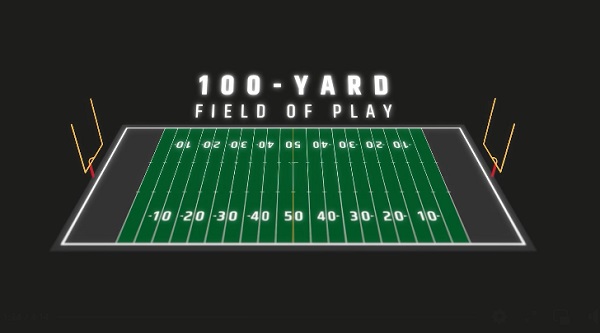

Sports1 day ago

Sports1 day agoCFL Evolution! Canadian Football League moving field goal posts, changing “rouge” rules, shrinking end zone and field size!

-

Bruce Dowbiggin1 day ago

Bruce Dowbiggin1 day agoChoking The Night Away: Can Blue Jays/ Tigers Recover?