Agriculture

Saskatchewan potash vital for world food

From Resource Works

Fertilizer Canada says the fertilizer industry contributes $23 billion a year to Canada’s economy and provides over 76,000 jobs.

A small potash extraction company in Manitoba calls Saskatchewan “the Niagara Falls of potash in Canada.”

The current 10 mines in Saskatchewan produced around 13 million tonnes in 2023, accounting for some 33% of global potash production, and exported 95% of it to more than 75 countries.

Potash mine No. 11 in Saskatchewan is working toward production in late 2026. That’s the $14-billion Jansen mine, owned by BHP, located 140 kilometres east of Saskatoon. It aims to produce around 8.5 million tonnes a year to start, and as much as 16–17 million tonnes a year in future stages.

With potash used primarily in agricultural fertilizers, Saskatchewan’s output is a key ingredient in global food security. Fertilizer is responsible for half of the world’s current food production.

As Real Agriculture points out: “Fertilizer production is not only an economic driver in Canada, but it is also a critical resource for customers around the world, especially in the United States.”

This is particularly important as Russia’s war on Ukraine has raised doubts about reliable supplies of potash from Russia, the world’s No. 2 producer, which produced 6.5 million tonnes in 2023.

In fertilizers, the potassium from potash increases plant growth and crop yields, strengthens roots, improves plants’ water efficiency, and increases pest and disease resistance. It improves the colour, texture, and taste of food. Natural Resources Canada adds: “Potassium is an essential element of the human diet, required for the growth and maintenance of tissues, muscles and organs, as well as the electrical activity of the heart.”

Canada’s federal government has included potash as one of 34 minerals and metals on its list of critical minerals.

Fertilizer Canada says the fertilizer industry contributes $23 billion a year to Canada’s economy and provides over 76,000 jobs.

The potash operations in Saskatchewan are in the Prairie Evaporite Deposit, the world’s largest known potash deposit, formed some 400 million years ago as an ancient inland sea evaporated. The deposits extend from central to south-central Saskatchewan into Manitoba and northern North Dakota. These deposits form the world’s largest potash reserves, at 1.1 billion tonnes.

Manitoba’s first potash mine is close to bringing its product to market. The PADCOM mine is 16 kilometres west of Russell, Manitoba, near the Manitoba-Saskatchewan border. The Gambler First Nation has acquired a one-fifth stake in the project.

PADCOM injects a heated mixture of water and salt underground to dissolve the potash, which is then pumped to the surface and crystallized. CEO Brian Clifford says this process is friendlier to the environment than the conventional method of mining underground and extracting ore from rock deposits.

Saskatchewan’s northern potash deposits are about 1,000 metres below the surface and are extracted using conventional mining techniques. To the south, deposits are anywhere from 1,500 to 2,400 metres deep and are mined using solution techniques.

PADCOM aims to produce 100,000 tonnes of potash per year, eventually growing to 250,000 tonnes per year. However, PADCOM president Daymon Guillas notes that across the Manitoba-Saskatchewan border, the Nutrien potash mine near Rocanville, Saskatchewan, produces five to seven million tonnes per year.

“In 36 hours, they produce more than we do in a year. Saskatchewan is the Niagara Falls of potash in Canada. Our little project is a drip, just a small drip out of the faucet.”

(New Brunswick once had a small potash mine, but it closed in 2016.)

Real Agriculture says: “Canadian-produced potash remains vital to the U.S.’s ability to produce enough corn for feed, ethanol production, and export requirements, at a time when the U.S. heightens its focus on reducing exposure to international integrated supply chains in favour of U.S. domestic supply chains.”

Writer Shaun Haney continues: “For the U.S. corn farmer, Canadian-produced potash is critical for achieving the top yields. According to StoneX, over the past three years, Canada accounts for roughly 87 per cent of potash imports by the U.S., while Russia sits at 9.5%.”

Agriculture

Lacombe meat processor scores $1.2 million dollar provincial tax credit to help expansion

Alberta’s government continues to attract investment and grow the provincial economy.

The province’s inviting and tax-friendly business environment, and abundant agricultural resources, make it one of North America’s best places to do business. In addition, the Agri-Processing Investment Tax Credit helps attract investment that will further diversify Alberta’s agriculture industry.

Beretta Farms is the most recent company to qualify for the tax credit by expanding its existing facility with the potential to significantly increase production capacity. It invested more than $10.9 million in the project that is expected to increase the plant’s processing capacity from 29,583 to 44,688 head of cattle per year. Eleven new employees were hired after the expansion and the company plans to hire ten more. Through the Agri-Processing Investment Tax Credit, Alberta’s government has issued Beretta Farms a tax credit of $1,228,735.

“The Agri-Processing Investment Tax Credit is building on Alberta’s existing competitive advantages for agri-food companies and the primary producers that supply them. This facility expansion will allow Beretta Farms to increase production capacity, which means more Alberta beef across the country, and around the world.”

“This expansion by Beretta Farms is great news for Lacombe and central Alberta. It not only supports local job creation and economic growth but also strengthens Alberta’s global reputation for producing high-quality meat products. I’m proud to see our government supporting agricultural innovation and investment right here in our community.”

The tax credit provides a 12 per cent non-refundable, non-transferable tax credit when businesses invest $10 million or more in a project to build or expand a value-added agri-processing facility in Alberta. The program is open to any food manufacturers and bio processors that add value to commodities like grains or meat or turn agricultural byproducts into new consumer or industrial goods.

Beretta Farms’ facility in Lacombe is a federally registered, European Union-approved harvesting and meat processing facility specializing in the slaughter, processing, packaging and distribution of Canadian and United States cattle and bison meat products to 87 countries worldwide.

“Our recent plant expansion project at our facility in Lacombe has allowed us to increase our processing capacities and add more job opportunities in the central Alberta area. With the support and recognition from the Government of Alberta’s tax credit program, we feel we are in a better position to continue our success and have the confidence to grow our meat brands into the future.”

Alberta’s agri-processing sector is the second-largest manufacturing industry in the province and meat processing plays an important role in the sector, generating millions in annual economic impact and creating thousands of jobs. Alberta continues to be an attractive place for agricultural investment due to its agricultural resources, one of the lowest tax rates in North America, a business-friendly environment and a robust transportation network to connect with international markets.

Quick facts

- Since 2023, there are 16 applicants to the Agri-Processing Investment Tax Credit for projects worth about $1.6 billion total in new investment in Alberta’s agri-processing sector.

- To date, 13 projects have received conditional approval under the program.

- Each applicant must submit progress reports, then apply for a tax credit certificate when the project is complete.

- Beretta Farms has expanded the Lacombe facility by 10,000 square feet to include new warehousing, cooler space and an office building.

- This project has the potential to increase production capacity by 50 per cent, thereby facilitating entry into more European markets.

Related information

Agriculture

Unstung Heroes: Canada’s Honey Bees are not Disappearing – They’re Thriving

Canada’s Bee Apocalypse began in 2008. That was the year the Canadian Association of Professional Apiculturists (CAPA) first reported unusually high rates of winter bee colony losses. At 35 percent, the winter die-off that year was more than twice the normal 15 percent rate of attrition.

“Successive annual losses at [these] levels … are unsustainable by Canadian beekeepers,” the CAPA warned. This set off an avalanche of dire media reports that now appear on a regular basis. Among the many examples over the years: Huge Honey Bee Losses Across Canada” and “Canada’s bee colonies see worst loss in 20 years”. As each of these stories reminds readers, the disappearance of honey bees will doom our food supply, given their crucial role in pollinating crops including canola, soyabeans, apples, tomatoes and berries.

This year the black-and-yellow striped Cassandras are back at work, with headlines shouting “Scientists warn of severe honeybee losses in 2025” and “The Bees are Disappearing Again”. If it’s spring, the bees must be disappearing. Again.

It is, however, mathematically impossible for any species to be in an allegedly continuous and calamitous state of decline over nearly two decades and never actually reduce in number. For despite the steady supply of grave warnings regarding their imminent collapse, Canada’s bees are actually buzzing with life.

In 2007, according to Statistics Canada, there were 589,000 honey bee colonies in Canada,; in 2024, they reached 829,000, just shy of 2021’s all-time high of 834,000. Figuring a conservative summertime average of 50,000 bees per colony, that means there are approximately 12 billion more honey bees in Canada today than when the Bee Apocalypse first hit.

As for beekeepers, their numbers have also been growing steadily, and now stand at 15,430 – the most recorded since 1988. As CAPA’s report acknowledges, “the Canadian beekeeping industry has been resilient and able to grow, as proven by the overall increase in the number of bee colonies since 2007 despite the difficulties faced every winter.”

How is this possible? As is usually the case where there’s a need to be filled, the market holds the answer.

It is true that Canadian honey bees face a long list of threats and challenges ranging from mites and viruses to Canada’s harsh winters. It is also true that they perform a crucial service in pollinating crops, the value of which is estimated at $7 billion annually. However, this underscores the fact that bees are a livestock bred for a particular agricultural purpose, no different from cattle, chickens or pen-raised salmon. They are a business.

And in spite of its alleged status as an environmental totem, the honey bee isn’t even native to North America. It was first imported by European settlers for its honey-making abilities in the 1600s. Since then, it has been cultivated with deliberate commercial intent – allowing it to outcompete native pollinators such as bumble bees and butterflies even though it is poorly suited to the local winter. (This highlights the irony of all those native-plant pollinator gardens virtuously installed in neighbourhoods across Canada that end up supporting an invasive honey bee population.)

The significance of the bee economy means that when a beehive collapses over the winter for whatever reason, beekeepers have plenty of motivation to regenerate that colony as swiftly as possible. While hives can create their own queens over time, this can be a slow process given the cold Canadian climate. The better option is to simply buy a new queen from a warmer country.

In 2024, Canada imported 300,000 queens worth $12 million, mostly from the U.S., Italy, Australia and Chile. That works out to $40 each. In a miracle of nature, each of these new queens can lay up to 2,500 eggs a day, and each egg takes just two to three weeks to reach full maturity as a worker or drone. It is also possible to import entire “bee packages” that include a queen and 8,000 to 10,000 bees.

As a result, even a devastating 50 percent winter loss rate, something that has occurred only rarely in Canada in individual provinces and never nationally, isn’t necessarily fatal to any beekeeping operation. The beekeeper can purchase imported queens in April, split their existing colonies and be back in business by May or June.

And regardless of the honey bee’s apparent difficulties with Canada’s unforgiving weather (efforts are ongoing to breed a hardier Canadian variant), there’s no shortage of bees worldwide. Earlier this year, the German statistical agency reported the global beehive count rose from 69 million in 1990 to 102 million in 2023. Another study looking back to 1961 by New Zealand researchers found the number of honey bee colonies has “nearly doubled” over this time, while honey production has “almost tripled.” As the New Zealand report observes, “Headlines of honey bee colony losses have given an

impression of large-scale global decline of the bee population that endangers beekeeping, and that the world is on the verge of mass starvation.” Such claims, the authors note, are “somewhat inaccurate.” In truth, things have never been better for bees around the world.

Here in Canada, the ability to import queens from other countries, together with their prodigious reproductive capabilities, backstops the amazing resiliency of the bee industry. Yes, bees die. Sometimes in large numbers. But – and this is the bit the headlines always ignore – they come back. Because the market needs them to come back.

If there is a real threat to Canada’s bee population, it’s not environmental. It’s the risk that unencumbered trade in bees might somehow be disrupted by tariffs or similar bone-headed human interventions. Left on their own, bees have no problem keeping busy.

The longer, original version of this story first appeared at C2CJournal.ca

-

Carbon Tax2 days ago

Carbon Tax2 days agoCanada’s Carbon Tax Is A Disaster For Our Economy And Oil Industry

-

Disaster2 days ago

Disaster2 days agoTexas flood kills 43 including children at Christian camp

-

Daily Caller2 days ago

Daily Caller2 days agoTrump’s One Big Beautiful Bill Resets The Energy Policy Playing Field

-

Business1 day ago

Business1 day agoThe Digital Services Tax Q&A: “It was going to be complicated and messy”

-

Alberta18 hours ago

Alberta18 hours agoAlberta Next: Immigration

-

International1 day ago

International1 day agoElon Musk forms America Party after split with Trump

-

Crime6 hours ago

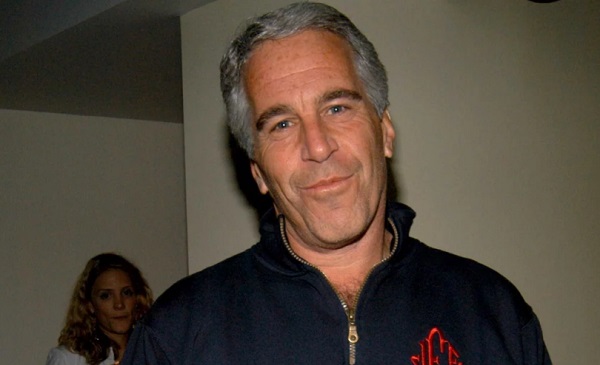

Crime6 hours agoNews Jeffrey Epstein did not have a client list, nor did he kill himself, Trump DOJ, FBI claim

-

COVID-194 hours ago

COVID-194 hours agoFDA requires new warning on mRNA COVID shots due to heart damage in young men