Agriculture

How Canadian Dairy Farms Can Adjust to New Dairy Demand

How Canadian Dairy Farms Can Adjust to New Dairy Demand

Many changes occurred around the world as a result of the coronavirus pandemic. In Canada, while schools and businesses closed, consumers flocked to the supermarkets to buy essentials.

Perishable goods flew off the shelves, resulting in limits being placed on items like dairy and poultry. The standard distribution system schedule put in place for dairy products could not keep up with buyers’ increased shopping.

While retail demand from grocers skyrocketed, orders from the foodservice industry plummeted. This has resulted in unforeseen fluctuations in the dairy market.

Hotels, restaurants, schools and eateries are closed or operating at limited capacity. As a result, there is now an enormous surplus of milk that has nowhere to go. Farmers are not equipped with storage spaces to accommodate the excess supply. Unlike agriculture products like potatoes, milk has to be sold immediately or risk spoilage.

Cows will continue producing milk, regardless of fluctuations in the market. While farmers have the option to reduce the size of their herd or change diet or nutrition, these things could prove detrimental when the market stabilizes.

The Supply Management System

A supply management system controls production quotas and imports for Canadian dairy, chicken, turkey and eggs. It was established in the1970s to coordinate production and demand while simultaneously controlling imports. By operating under this method, prices are stabilized for both producers and consumers.

A national agency represents each industry, and they are in charge of setting production levels that match provincial demand. Farmers in each province are allocated production quotas that are meant to prevent surpluses or shortages.

The original quotas were based on consumer needs pre-pandemic. As a result of these unforeseen events, farmers must now adjust to the new Canadian dairy demand. Here are four main ways farmers can adapt to the changing times.

- Dump the Milk

Producers say that discarding raw milk is inevitable at this stage. Farmers are reporting that they have been asked to take turns dumping milk. Although they’re paid for it, the waste could amount to as much as 5 million litres every week.

This disposal method is unsustainable and should only be utilized while the market is above capacity. Cows must continue to be milked to keep them comfortable and healthy, and production must continue to ensure product availability in retail stores.

- Donate to Food Banks

Rather than dumping milk, some farmers have begun donating to food banks to support Canadians in need. While this is a positive form of dispersing the milk surplus, it has the potential to overwhelm food banks that may not have the storage capacity to support this influx.

Additionally, the raw milk provided from farmers must be processed, which complicates the standard donation process.

- Improve Operations

Dairy farmers should focus on improving operations to become more efficient and cost-effective. Many producers have begun investing in updated equipment and robotics to save time and money. Competition is set to increase as a result of import growth projected for the next decade. To maintain a market edge, operations should be improved and simplified wherever possible.

- Expand or Retire

In 2019, the Canadian federal government announced an aid package valued at $1.75 billion to compensate supply-managed dairy producers over an eight-year period. The Dairy Direct Payment Program is one part of this aid package and provides $345 million payments as compensation during 2019 and 2020.

The aid package was proposed as a result of import shifts. The Canadian government has opened part of its domestic market to foreign producers as part of several free-trade negotiations. To adapt to increased competition from foreign products, Canadian producers should plan to expand their operations or retire. Larger farms will be able to sustain demand while simultaneously upgrading their methods to be constantly improving.

Smaller producers may not be able to afford the necessary production updates to keep up with competitors.

Future Demand

These are unprecedented circumstances. As schools, businesses and restaurants reopen, dairy demand will increase. With indoor capacity requirements and shifts in consumer trends, consumption levels will undoubtedly continue to fluctuate.

While farmers should take steps to dispose of surplus responsibly, they should not halt production or decrease their operation size.

Read more from Emily Folk

I’m Emily Folk, and I grew up in a small town in Pennsylvania. Growing up I had a love of animals, and after countless marathons of watching Animal Planet documentaries, I developed a passion for ecology and conservation. You can read more of my work by clicking this link: Conservation Folks.

Canadian Federal Government Taking Measures to Reduce Impact of COVID-19 on Agriculture

Agriculture

Lacombe meat processor scores $1.2 million dollar provincial tax credit to help expansion

Alberta’s government continues to attract investment and grow the provincial economy.

The province’s inviting and tax-friendly business environment, and abundant agricultural resources, make it one of North America’s best places to do business. In addition, the Agri-Processing Investment Tax Credit helps attract investment that will further diversify Alberta’s agriculture industry.

Beretta Farms is the most recent company to qualify for the tax credit by expanding its existing facility with the potential to significantly increase production capacity. It invested more than $10.9 million in the project that is expected to increase the plant’s processing capacity from 29,583 to 44,688 head of cattle per year. Eleven new employees were hired after the expansion and the company plans to hire ten more. Through the Agri-Processing Investment Tax Credit, Alberta’s government has issued Beretta Farms a tax credit of $1,228,735.

“The Agri-Processing Investment Tax Credit is building on Alberta’s existing competitive advantages for agri-food companies and the primary producers that supply them. This facility expansion will allow Beretta Farms to increase production capacity, which means more Alberta beef across the country, and around the world.”

“This expansion by Beretta Farms is great news for Lacombe and central Alberta. It not only supports local job creation and economic growth but also strengthens Alberta’s global reputation for producing high-quality meat products. I’m proud to see our government supporting agricultural innovation and investment right here in our community.”

The tax credit provides a 12 per cent non-refundable, non-transferable tax credit when businesses invest $10 million or more in a project to build or expand a value-added agri-processing facility in Alberta. The program is open to any food manufacturers and bio processors that add value to commodities like grains or meat or turn agricultural byproducts into new consumer or industrial goods.

Beretta Farms’ facility in Lacombe is a federally registered, European Union-approved harvesting and meat processing facility specializing in the slaughter, processing, packaging and distribution of Canadian and United States cattle and bison meat products to 87 countries worldwide.

“Our recent plant expansion project at our facility in Lacombe has allowed us to increase our processing capacities and add more job opportunities in the central Alberta area. With the support and recognition from the Government of Alberta’s tax credit program, we feel we are in a better position to continue our success and have the confidence to grow our meat brands into the future.”

Alberta’s agri-processing sector is the second-largest manufacturing industry in the province and meat processing plays an important role in the sector, generating millions in annual economic impact and creating thousands of jobs. Alberta continues to be an attractive place for agricultural investment due to its agricultural resources, one of the lowest tax rates in North America, a business-friendly environment and a robust transportation network to connect with international markets.

Quick facts

- Since 2023, there are 16 applicants to the Agri-Processing Investment Tax Credit for projects worth about $1.6 billion total in new investment in Alberta’s agri-processing sector.

- To date, 13 projects have received conditional approval under the program.

- Each applicant must submit progress reports, then apply for a tax credit certificate when the project is complete.

- Beretta Farms has expanded the Lacombe facility by 10,000 square feet to include new warehousing, cooler space and an office building.

- This project has the potential to increase production capacity by 50 per cent, thereby facilitating entry into more European markets.

Related information

Agriculture

Canada’s supply management system is failing consumers

This article supplied by Troy Media.

The supply management system is cracking. With imports climbing, strict quotas in place and Bill C202 on the table, we’re struggling to feed ourselves

Canada’s supply management system, once seen as a pillar of food security and agricultural self-sufficiency, is failing at its most basic function:

ensuring a reliable domestic supply.

According to the Canadian Association of Regulated Importers, Canada imported more than 66.9 million kilograms of chicken as of June 14, a 54.6 per cent increase from the same period last year. That’s enough to feed 3.4 million Canadians for a full year based on average poultry consumption—roughly 446 million meals. Under a tightly managed quota system, those meals were supposed to be produced domestically. Instead imports now account for more than 12 per cent of this year’s domestic chicken production, revealing a growing dependence on foreign supply.

Supply management is Canada’s system for regulating dairy, poultry and egg production. It uses quotas and fixed prices to match domestic supply with demand while limiting imports, intended to protect farmers from global price swings and ensure stable supply.

To be fair, the avian influenza outbreak has disrupted poultry production and partially explains the shortfall. But even with that disruption, the numbers are staggering. Imports under trade quotas set by the World Trade Organization, the Canada-United States Mexico Agreement and the Comprehensive and Progressive Agreement for Trans-Pacific Partnership are running at or near their allowable monthly share—known as pro-rata

levels—signalling not just opportunity, but urgency. Supplementary import permits, meant to be used only in emergencies, have already surpassed 48 million kilograms, exceeding total annual import volumes in some previous years. This isn’t a seasonal hiccup. It’s a systemic failure.

The system, designed to buffer domestic markets from global volatility, is cracking under internal strain. When emergency imports become routine, we have to ask: what exactly is being managed?

Canada’s most recent regulated chicken production cycle, which ended May 31, saw one of the worst shortfalls in over 50 years. Strict quota limits stopped farmers from producing more to meet demand, leaving consumers with higher grocery bills and more imported food, shaking public confidence in the system.

Some defenders insist this is an isolated event. It’s not. For the second straight week, Canada has hit pro-rata import levels across all chicken categories. Bone-in and processed poultry, once minor players in emergency import programs, are now essential just to keep shelves stocked.

And the dysfunction doesn’t stop at chicken. Egg imports under the shortage allocation program have already topped 14 million dozen, a 104 per cent jump from last year. Not long ago, Canadians were mocking high U.S. egg prices. Now theirs have fallen. Ours haven’t.

All this in a country with $30 billion in quota value, supposedly designed to protect domestic production and reduce reliance on imports. Instead, we’re importing more and paying more.

Rather than addressing these failures, Ottawa is looking to entrench them. Bill C202, now before the Senate, seeks to shield supply management from future trade talks, making reform even harder. So we must ask: is this really what we’re protecting?

Meanwhile, our trading partners are taking full advantage. Chile, for instance, has increased chicken exports to Canada by more than 63 per cent, now accounting for nearly 96 per cent of CPTPP-origin imports. While Canada doubles down on protectionism, others are gaining long-term footholds in our market.

It’s time to face the facts. Supply management no longer guarantees supply. When a system meant to ensure resilience becomes a source of fragility, it’s no longer an asset—it’s an economic liability.

Dr. Sylvain Charlebois is a Canadian professor and researcher in food distribution and policy. He is senior director of the Agri-Food Analytics Lab at Dalhousie University and co-host of The Food Professor Podcast. He is frequently cited in the media for his insights on food prices, agricultural trends, and the global food supply chain.

Troy Media empowers Canadian community news outlets by providing independent, insightful analysis and commentary. Our mission is to support local media in helping Canadians stay informed and engaged by delivering reliable content that strengthens community connections and deepens understanding across the country.

-

armed forces1 day ago

armed forces1 day agoCanada’s Military Can’t Be Fixed With Cash Alone

-

Alberta1 day ago

Alberta1 day agoCOVID mandates protester in Canada released on bail after over 2 years in jail

-

International1 day ago

International1 day agoTrump transportation secretary tells governors to remove ‘rainbow crosswalks’

-

Business1 day ago

Business1 day agoCanada’s loyalty to globalism is bleeding our economy dry

-

Business1 day ago

Business1 day agoCarney’s spending makes Trudeau look like a cheapskate

-

Alberta1 day ago

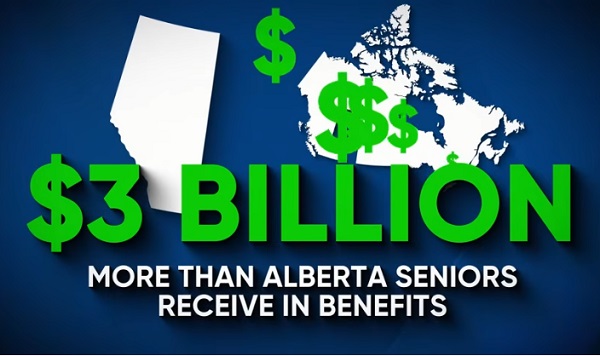

Alberta1 day agoAlberta Next: Alberta Pension Plan

-

Crime2 days ago

Crime2 days agoProject Sleeping Giant: Inside the Chinese Mercantile Machine Linking Beijing’s Underground Banks and the Sinaloa Cartel

-

C2C Journal23 hours ago

C2C Journal23 hours agoCanada Desperately Needs a Baby Bump