Alberta

Canada’s advantage as the world’s demand for plastic continues to grow

From the Canadian Energy Centre

By Will Gibson

‘The demand for plastics reflects how essential they are in our lives’

From the clothes on your back to the containers for household products to the pipes and insulation in your home, plastics are interwoven into the fabric of day-to-day life for most Canadians.

And that reliance is projected to grow both in Canada and around the world in the next three decades

The Global Plastics Outlook, published by the Paris-based Organization for Economic Co-operation and Development (OECD), forecasts the use of plastics globally will nearly triple by 2060, driven by economic and population growth.

The use of plastics is projected to double in OECD countries like Canada, the United States and European nations, but the largest increases will take place in Asia and Africa.

“The demand for plastics reflects how essential they are in our lives, whether it is packaging, textiles, building materials or medical equipment,” says Christa Seaman, vice-president, plastics with the Chemical Industry Association of Canada (CIAC), which represents Canada’s plastics producers.

She says as countries look to meet climate and sustainability goals, demand for plastic will grow.

“Plastics in the market today demonstrate their value to our society. Plastics are used to make critical components for solar panels and wind turbines. But they also can play a role in reducing weight in transportation or in ensuring goods that are transported have less weight in their packaging or in their products.”

Canada produces about $35 billion worth of plastic resin and plastic products per year, or over five per cent of Canadian manufacturing sales, according to a 2019 report published by the federal government.

Seaman says Canadian plastic producers have competitive advantages that position them to grow as demand rises at home and abroad. In Alberta, a key opportunity is the abundant supply of natural gas used to make plastic resin.

“As industry and consumer expectations shift for production to reduce emissions, Canada, and particularly Alberta, are extremely well placed to meet increased demand thanks to its supply of low-carbon feedstock. Going forward, production with less emissions is going to be important for companies,” Seaman says.

“You can see that with Dow Chemical’s decision to spend $8.8 billion on a net zero facility in Alberta.”

While modern life would not be possible without plastics, the CIAC says there needs to be better post-use management of plastic products including advanced recycling, or a so-called “circular economy” where plastics are seen as a resource or feedstock for new products, not a waste.

Some companies have already started making significant investments to generate recyclable plastics.

For example, Inter Pipeline Ltd.’s $4.3 billion Heartland Petrochemical Complex near Edmonton started operating in 2023. It produces a recyclable plastic called polypropylene from propane, with 65 per cent lower emissions than the global average thanks to the facility’s integrated design.

Achieving a circular economy – where 90 per cent of post-consumer plastic waste is diverted or recycled – would benefit Canada’s economy, according to the CIAC.

A Deloitte study, commissioned by Environment & Climate Change Canada, estimated diverting or reusing 90 per cent of post-consumer plastic waste by 2030 will save $500 million annually while creating 42,000 direct and indirect jobs. It would also cut Canada’s annual CO2 emissions by 1.8 megatonnes.

Right now, about 85 per cent of plastics end up in Canada’s landfills. To reach the 90 per cent diversion rate, Seaman says Canada must improve its infrastructure to collect and process the plastic waste currently being landfilled.

But she also says the industry rather than municipalities need to take responsibility for recycling plastic waste.

“This concept is referred to as extended producer responsibility. Municipalities have the responsibility for managing recycling within a waste management system. Given the competing costs and priorities, they don’t have the incentive to invest into recycling infrastructure when landfill space was the most cost-effective solution for them,” she says.

“Putting that responsibility on the producers who put the products on the market makes the most sense…The industry is adapting, and we hope government policy will recognize this opportunity for Canada to meet our climate goals while growing our economy.”

Agriculture

Lacombe meat processor scores $1.2 million dollar provincial tax credit to help expansion

Alberta’s government continues to attract investment and grow the provincial economy.

The province’s inviting and tax-friendly business environment, and abundant agricultural resources, make it one of North America’s best places to do business. In addition, the Agri-Processing Investment Tax Credit helps attract investment that will further diversify Alberta’s agriculture industry.

Beretta Farms is the most recent company to qualify for the tax credit by expanding its existing facility with the potential to significantly increase production capacity. It invested more than $10.9 million in the project that is expected to increase the plant’s processing capacity from 29,583 to 44,688 head of cattle per year. Eleven new employees were hired after the expansion and the company plans to hire ten more. Through the Agri-Processing Investment Tax Credit, Alberta’s government has issued Beretta Farms a tax credit of $1,228,735.

“The Agri-Processing Investment Tax Credit is building on Alberta’s existing competitive advantages for agri-food companies and the primary producers that supply them. This facility expansion will allow Beretta Farms to increase production capacity, which means more Alberta beef across the country, and around the world.”

“This expansion by Beretta Farms is great news for Lacombe and central Alberta. It not only supports local job creation and economic growth but also strengthens Alberta’s global reputation for producing high-quality meat products. I’m proud to see our government supporting agricultural innovation and investment right here in our community.”

The tax credit provides a 12 per cent non-refundable, non-transferable tax credit when businesses invest $10 million or more in a project to build or expand a value-added agri-processing facility in Alberta. The program is open to any food manufacturers and bio processors that add value to commodities like grains or meat or turn agricultural byproducts into new consumer or industrial goods.

Beretta Farms’ facility in Lacombe is a federally registered, European Union-approved harvesting and meat processing facility specializing in the slaughter, processing, packaging and distribution of Canadian and United States cattle and bison meat products to 87 countries worldwide.

“Our recent plant expansion project at our facility in Lacombe has allowed us to increase our processing capacities and add more job opportunities in the central Alberta area. With the support and recognition from the Government of Alberta’s tax credit program, we feel we are in a better position to continue our success and have the confidence to grow our meat brands into the future.”

Alberta’s agri-processing sector is the second-largest manufacturing industry in the province and meat processing plays an important role in the sector, generating millions in annual economic impact and creating thousands of jobs. Alberta continues to be an attractive place for agricultural investment due to its agricultural resources, one of the lowest tax rates in North America, a business-friendly environment and a robust transportation network to connect with international markets.

Quick facts

- Since 2023, there are 16 applicants to the Agri-Processing Investment Tax Credit for projects worth about $1.6 billion total in new investment in Alberta’s agri-processing sector.

- To date, 13 projects have received conditional approval under the program.

- Each applicant must submit progress reports, then apply for a tax credit certificate when the project is complete.

- Beretta Farms has expanded the Lacombe facility by 10,000 square feet to include new warehousing, cooler space and an office building.

- This project has the potential to increase production capacity by 50 per cent, thereby facilitating entry into more European markets.

Related information

Alberta

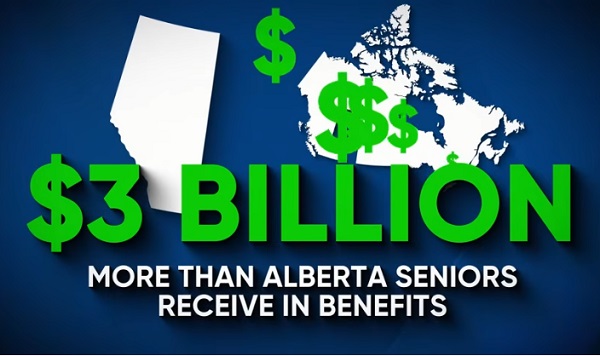

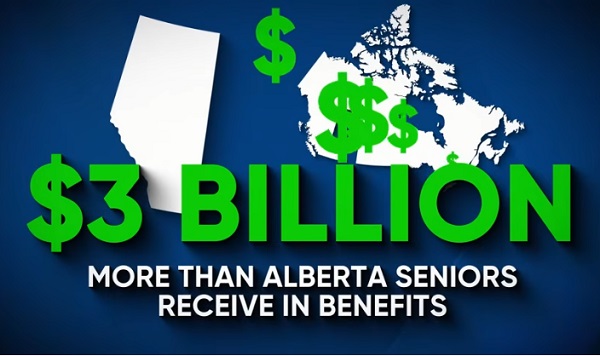

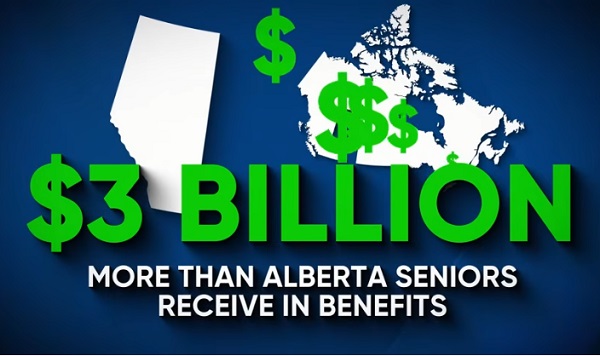

Alberta Next: Alberta Pension Plan

From Premier Danielle Smith and Alberta.ca/Next

Let’s talk about an Alberta Pension Plan for a minute.

With our young Alberta workforce paying billions more into the CPP each year than our seniors get back in benefits, it’s time to ask whether we stay with the status quo or create our own Alberta Pension Plan that would guarantee as good or better benefits for seniors and lower premiums for workers.

I want to hear your perspective on this idea and please check out the video. Get the facts. Join the conversation.

Visit Alberta.ca/next

-

Agriculture2 days ago

Agriculture2 days agoCanada’s supply management system is failing consumers

-

Business1 day ago

Business1 day agoCanada’s loyalty to globalism is bleeding our economy dry

-

armed forces1 day ago

armed forces1 day agoCanada’s Military Can’t Be Fixed With Cash Alone

-

Alberta24 hours ago

Alberta24 hours agoAlberta Next: Alberta Pension Plan

-

Alberta1 day ago

Alberta1 day agoCOVID mandates protester in Canada released on bail after over 2 years in jail

-

International1 day ago

International1 day agoTrump transportation secretary tells governors to remove ‘rainbow crosswalks’

-

Business1 day ago

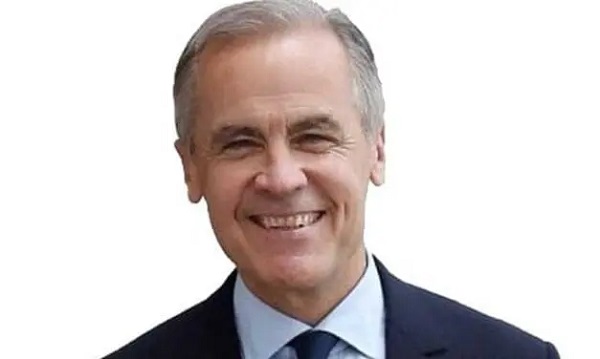

Business1 day agoCarney’s spending makes Trudeau look like a cheapskate

-

Crime2 days ago

Crime2 days agoProject Sleeping Giant: Inside the Chinese Mercantile Machine Linking Beijing’s Underground Banks and the Sinaloa Cartel