Canadian Energy Centre

Top 10 good news stories about Canadian energy in 2024

From the Canadian Energy Centre

Record oil production, more Indigenous ownership and inching closer to LNG

It’s likely 2024 will go down in history as a turning point for Canadian energy, despite challenging headwinds from federal government policy.

Here’s some of the good news.

10. New carbon capture and storage (CCS) projects to proceed

In June, Shell announced it will proceed with the Polaris and Atlas CCS projects, expanding emissions reduction at the company’s Scotford energy and chemicals park near Edmonton.

Polaris is designed to capture approximately 650,000 tonnes of CO2 per year, or the equivalent annual emissions of about 150,000 gasoline-powered cars. The CO2 will be transported by a 22-kilometre pipeline to the Atlas underground storage hub.

The projects build on Shell’s experience at the Quest CCS project, also located at the Scotford complex. Since 2015, Quest has stored more than eight million tonnes of CO2. Polaris and Atlas are targeted for startup in 2028.

Meanwhile, Entropy Inc. announced in July it will proceed with its Glacier Phase 2 CCS project. Located at the Glacier gas plant near Grande Prairie, the project is expected onstream in mid-2026 and will capture 160,000 tonnes of emissions per year.

Since 2015, CCS operations in Alberta have safely stored roughly 14 million tonnes of CO2, or the equivalent emissions of more than three million cars.

9. Canada’s U.S. oil exports reach new record

Expanded export capacity at the Trans Mountain Westridge Terminal. Photo courtesy Trans Mountain Corporation

Canada’s exports of oil and petroleum products to the United States averaged a record 4.6 million barrels per day in the first nine months of 2024, according to the U.S. Energy Information Administration.

Demand from Midwest states increased, along with the U.S. Gulf Coast, the world’s largest refining hub. Canadian sales to the U.S. West Coast also increased, enabled by the newly completed Trans Mountain Pipeline Expansion.

8. Alberta’s oil production never higher

In early December, ATB Economics analyst Rob Roach reported that Alberta’s oil production has never been higher, averaging 3.9 million barrels per day in the first 10 months of the year.

This is about 190,000 barrels per day higher than during the same period in 2023, enabled by the Trans Mountain expansion, Roach noted.

7. Indigenous energy ownership spreads

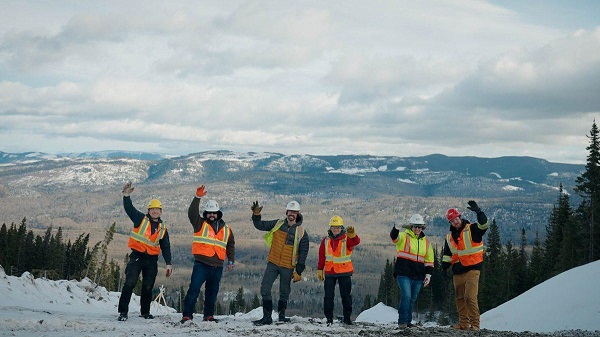

Communities of Wapiscanis Waseskwan Nipiy Limited Partnership in December 2023. Photo courtesy Alberta Indigenous Opportunities Corporation

In September, the Bigstone Cree Nation became the latest Indigenous community to acquire an ownership stake in an Alberta energy project.

Bigstone joined 12 other First Nations and Métis settlements in the Wapiscanis Waseskwan Nipiy Holding Limited Partnership, which holds 85 per cent ownership of Tamarack Valley Energy’s Clearwater midstream oil and gas assets.

The Alberta Indigenous Opportunities Corporation (AIOC) is backstopping the agreement with a total $195 million loan guarantee.

In its five years of operations, the AIOC has supported more than 60 Indigenous communities taking ownership of energy projects, with loan guarantees valued at more than $725 million.

6. Oil sands emissions intensity goes down

A November report from S&P Global Commodity said that oil sands production growth is beginning to rise faster than emissions growth.

While oil sands production in 2023 was nine per cent higher than in 2019, total emissions rose by just three per cent.

“This is a notable, significant change in oil sands emissions,” said Kevin Birn, head of S&P Global’s Centre for Emissions Excellence.

Average oil sands emissions per barrel, or so-called “emissions intensity” is now 28 per cent lower than it was in 2009.

5. Oil and gas producers beat methane target, again

Data released by the Alberta Energy Regulator in November 2024 confirmed that methane emissions from conventional oil and gas production in the province continue to go down, exceeding government targets.

In 2022, producers reached the province’s target to reduce methane emissions by 45 per cent compared to 2014 levels by 2025 three years early.

The new data shows that as of 2023, methane emissions have been reduced by 52 per cent.

4. Cedar LNG gets the green light to proceed

Haisla Nation Chief Councillor Crystal Smith and Pembina Pipeline Corporation CEO Scott Burrows announce the Cedar LNG positive final investment decision on June 25, 2024. Photo courtesy Cedar LNG

The world’s first Indigenous majority-owned liquefied natural gas (LNG) project is now under construction on the coast of Kitimat, B.C., following a positive final investment decision in June.

Cedar LNG is a floating natural gas export terminal owned by the Haisla Nation and Pembina Pipeline Corporation. It will have capacity to produce 3.3 million tonnes of LNG per year for export overseas, primarily to meet growing demand in Asia.

The $5.5-billion project will receive natural gas through the Coastal GasLink pipeline. Peak construction is expected in 2026, followed by startup in late 2028.

3. Coastal GasLink Pipeline goes into service

The countdown is on to Canada’s first large-scale LNG exports, with the official startup of the $14.5-billion Coastal GasLink Pipeline in November.

The 670-kilometre pipeline transports natural gas from near Dawson Creek, B.C. to the LNG Canada project at Kitimat, where it will be supercooled and transformed into LNG.

LNG Canada will have capacity to export 14 million tonnes of LNG per year to overseas markets, primarily in Asia, where it is expected to help reduce emissions by displacing coal-fired power.

The terminal’s owners – Shell, Petronas, PetroChina, Mitsubishi and Korea Gas Corporation – are ramping up natural gas production to record rates, according to RBN Energy.

RBN analyst Martin King expects the first shipments to leave LNG Canada by early next year, setting up for commercial operations in mid-2025.

2. Construction starts on $8.9 billion net zero petrochemical plant

In April, construction commenced near Edmonton on the world’s first plant designed to produce polyethylene — a widely used, recyclable plastic — with net zero scope 1 and 2 emissions.

Dow Chemicals’ $8.9 billion Path2Zero project is an expansion of the company’s manufacturing site in Fort Saskatchewan. Using natural gas as a feedstock, it will incorporate CCS to reduce emissions.

According to business development agency Edmonton Global, the project is spurring a boom in the region, with nearly 200 industrial projects worth about $96 billion now underway or nearing construction.

Dow’s plant is scheduled for startup in 2027.

1. Trans Mountain Pipeline Expansion completed

The “Golden Weld” marked mechanical completion of construction for the Trans Mountain Expansion Project on April 11, 2024. Photo courtesy Trans Mountain Corporation

The long-awaited $34-billion Trans Mountain Pipeline Expansion officially went into service in May, in a game-changer for Canadian energy with ripple effects around the world.

The 590,000 barrel-per-day expansion for the first time gives customers outside the United States access to large volumes of Canadian oil, with the benefits flowing to Canada’s economy.

According to the Canada Energy Regulator, exports to non-U.S. locations more than doubled following the expansion startup, averaging 420,000 barrels per day compared to about 130,000 barrels per day in 2023.

The value of Canadian oil exports to Asia has soared from effectively zero to a monthly average of $515 million between June and October, according to ATB Economics.

Alberta

The case for expanding Canada’s energy exports

From the Canadian Energy Centre

For Canada, the path to a stronger economy — and stronger global influence — runs through energy.

That’s the view of David Detomasi, a professor at the Smith School of Business at Queen’s University.

Detomasi, author of Profits and Power: Navigating the Politics and Geopolitics of Oil, argues that there is a moral case for developing Canada’s energy, both for Canadians and the world.

CEC: What does being an energy superpower mean to you?

DD: It means Canada is strong enough to affect the system as a whole by its choices.

There is something really valuable about Canada’s — and Alberta’s — way of producing carbon energy that goes beyond just the monetary rewards.

CEC: You talk about the moral case for developing Canada’s energy. What do you mean?

DD: I think the default assumption in public rhetoric is that the environmental movement is the only voice speaking for the moral betterment of the world. That needs to be challenged.

That public rhetoric is that the act of cultivating a powerful, effective economic engine is somehow wrong or bad, and that efforts to create wealth are somehow morally tainted.

I think that’s dead wrong. Economic growth is morally good, and we should foster it.

Economic growth generates money, and you can’t do anything you want to do in social expenditures without that engine.

Economic growth is critical to doing all the other things we want to do as Canadians, like having a publicly funded health care system or providing transfer payments to less well-off provinces.

Over the last 10 years, many people in Canada came to equate moral leadership with getting off of oil and gas as quickly as possible. I think that is a mistake, and far too narrow.

Instead, I think moral leadership means you play that game, you play it well, and you do it in our interest, in the Canadian way.

We need a solid base of economic prosperity in this country first, and then we can help others.

CEC: Why is it important to expand Canada’s energy trade?

DD: Canada is, and has always been, a trading nation, because we’ve got a lot of geography and not that many people.

If we don’t trade what we have with the outside world, we aren’t going to be able to develop economically, because we don’t have the internal size and capacity.

Historically, most of that trade has been with the United States. Geography and history mean it will always be our primary trade partner.

But the United States clearly can be an unreliable partner. Free and open trade matters more to Canada than it does to the U.S. Indeed, a big chunk of the American people is skeptical of participating in a global trading system.

As the United States perhaps withdraws from the international trading and investment system, there’s room for Canada to reinforce it in places where we can use our resource advantages to build new, stronger relationships.

One of these is Europe, which still imports a lot of gas. We can also build positive relationships with the enormous emerging markets of China and India, both of whom want and will need enormous supplies of energy for many decades.

I would like to be able to offer partners the alternative option of buying Canadian energy so that they are less reliant on, say, Iranian or Russian energy.

Canada can also maybe eventually help the two billion people in the world currently without energy access.

CEC: What benefits could Canadians gain by becoming an energy superpower?

DD: The first and primary responsibility of our federal government is to look after Canada. At the end of the day, the goal is to improve Canada’s welfare and enhance its sovereignty.

More carbon energy development helps Canada. We have massive debt, an investment crisis and productivity problems that we’ve been talking about forever. Economic and job growth are weak.

Solving these will require profitable and productive industries. We don’t have so many economic strengths in this country that we can voluntarily ignore or constrain one of our biggest industries.

The economic benefits pay for things that make you stronger as a country.

They make you more resilient on the social welfare front and make increasing defence expenditures, which we sorely need, more affordable. It allows us to manage the debt that we’re running up, and supports deals for Canada’s Indigenous peoples.

CEC: Are there specific projects that you advocate for to make Canada an energy superpower?

DD: Canada’s energy needs egress, and getting it out to places other than the United States. That means more transport and port facilities to Canada’s coasts.

We also need domestic energy transport networks. People don’t know this, but a big chunk of Ontario’s oil supply runs through Michigan, posing a latent security risk to Ontario’s energy security.

We need to change the perception that pipelines are evil. There’s a spiderweb of them across the globe, and more are being built.

Building pipelines here, with Canadian technology and know-how, builds our competitiveness and enhances our sovereignty.

Economic growth enhances sovereignty and provides the resources to do other things. We should applaud and encourage it, and the carbon energy sector can lead the way.

Business

Oil tanker traffic surges but spills stay at zero after Trans Mountain Expansion

From the Canadian Energy Centre

Bigger project maintains decades-long marine safety record

The Trans Mountain system continues its decades-long record of zero marine spills, even as oil tanker traffic has surged more than 800 per cent since the pipeline’s expansion in May 2024.

The number of tankers calling at Trans Mountain’s Westridge Marine Terminal in the Port of Vancouver in one month now rivals the number that used to go through in one year.

A global trend toward safer tanker operations

Trans Mountain’s safe operations are part of a worldwide trend. Global oil tanker traffic is up, yet spills are down, according to the International Tanker Owners Pollution Federation, a London, UK-based nonprofit that provides data and response support.

Transport Canada reports a 95 per cent drop in ship-source oil spills and spill volumes since the 1970s, driven by stronger ship design, improved response and better regulations.

“Tankers are now designed much more safely. They are double-hulled and compartmentalized to mitigate spills,” said Mike Lowry, spokesperson for the Western Canada Marine Response Corporation (WCMRC).

WCMRC: Ready to protect the West Coast

One of WCMRC’s new response vessels arrives in Barkley Sound. Photo courtesy Western Canada Marine Response Corporation

From eight marine bases including Vancouver and Prince Rupert, WCMRC stands at the ready to protect all 27,000 kilometres of Canada’s western coastline.

Lowry sees the corporation as similar to firefighters — training to respond to an event they hope they never have to see.

In September, it conducted a large-scale training exercise for a worst-case spill scenario. This included the KJ Gardner — Canada’s largest spill response vessel and a part of WCMRC’s fleet since 2024.

“It’s part of the work we do to make sure everybody is trained and prepared to use our assets just in case,” Lowry said.

Expanding capacity for Trans Mountain

The K.J. Gardner is the largest-ever spill response vessel in Canada. Photo courtesy Western Canada Marine Response Corporation

WCMRC’s fleet and capabilities were doubled with a $170-million expansion to support the Trans Mountain project.

Between 2012 and 2024, the company grew from 13 people and $12 million in assets to more than 200 people and $213 million in assets.

“About 80 per cent of our employees are mariners who work as deckhands, captains and marine engineers on our vessels,” Lowry said.

“Most of the incidents we respond to are small marine diesel spills — the last one was a fuel leak from a forest logging vessel near Nanaimo — so we have deployed our fleet in other ways.”

Tanker safety starts with strong rules and local expertise

Tanker loading at the Westridge Marine Terminal in the Port of Vancouver. Photo courtesy Trans Mountain Corporation

Speaking on the ARC Energy Ideas podcast, Trans Mountain CEO Mark Maki said tanker safety starts with strong regulations, including the use of local pilots to guide vessels into the harbour.

“On the Mississippi River, you have Mississippi River pilots because they know how the river behaves. Same thing would apply here in Vancouver Harbour. Tides are strong, so people who are familiar with the harbor and have years and decades of experience are making sure the ships go in and out safely,” Maki said.

“A high standard is applied to any ship that calls, and our facility has to meet very strict requirements. And we have rejected ships, just said, ‘Nope, that one doesn’t fit the bill.’ A ship calling on our facilities is very, very carefully looked at.”

Working with communities to protect sensitive areas

Beyond escorting ships and preparing for spills, WCMRC partners with coastal communities to map sensitive areas that need rapid protection including salmon streams, clam beds and culturally important sites like burial grounds.

“We want to empower communities and nations to be more prepared and involved,” Lowry said.

“They can help us identify and protect the areas that they value or view as sensitive by working with our mapping people to identify those areas in advance. If we know where those are ahead of time, we can develop a protection strategy for them.”

-

Alberta1 day ago

Alberta1 day agoThe Recall Trap: 21 Alberta MLA’s face recall petitions

-

illegal immigration1 day ago

illegal immigration1 day agoUS Notes 2.5 million illegals out and counting

-

International1 day ago

International1 day agoTyler Robinson shows no remorse in first court appearance for Kirk assassination

-

2025 Federal Election2 days ago

2025 Federal Election2 days agoToo Close for Comfort: Carney Floor Crosser Comes From a Riding Tainted by PRC Interference

-

Business2 days ago

Business2 days agoHigh-speed rail between Toronto and Quebec City a costly boondoggle for Canadian taxpayers

-

Business2 days ago

Business2 days agoThe world is no longer buying a transition to “something else” without defining what that is

-

Energy1 day ago

Energy1 day agoCanada’s future prosperity runs through the northwest coast

-

Daily Caller18 hours ago

Daily Caller18 hours ago‘There Will Be Very Serious Retaliation’: Two American Servicemen, Interpreter Killed In Syrian Attack