Alberta

The Alberta energy transition you haven’t heard about

From the Canadian Energy Centre

Horizontal drilling technology and more investment in oil production have fundamentally changed the industry

There’s extensive discussion today about energy transition and transformation. Its primary focus is a transition from fossil fuels to lower-carbon energy sources.

But in Alberta, a fundamental but different energy transition has already taken place, and its ripple effects stretch into businesses and communities across the province.

The shift has affected the full spectrum of oil and gas activity: where production happens, how it’s done, who does it and what type of energy is produced.

Oil and gas development in Alberta today largely happens in different places and uses different technologies than 20 years ago. As a result, the companies that support activity and the communities where operations happen have had to change.

Regional Shift

For the first decade of this century, in terms of numbers of wells, most drilling activity happened in central and southeast Alberta, with companies primarily using vertical wells to target conventional shallow natural gas deposits.

In 2005, producers drilled more than 8,000 natural gas wells in these areas, according to Alberta Energy Regulator (AER) records.

But then, three things happened. The price of natural gas declined, the price of oil went up and new horizontal drilling technology unlocked vast energy resources that were previously uneconomic to produce.

By 2015, the amount of natural gas wells companies drilled in central and southeast Alberta was just 256. In 2023, the number dropped to only 50. Over approximately 20 years, activity dropped by 99 per cent.

Where did the investment capital go? The oil sands and heavy oil reserves of Alberta’s northeast and shale plays, including the Montney and Duvernay, in the province’s foothills and northwest.

Nearly 60 per cent of activity outside of the oil-rich northeast occurred in central and southeast Alberta in 2005. By 2023, overall oil and gas drilling in those regions had dropped by 30 per cent, while at the same time increasing by 159 per cent in the foothills and northwest.

“The migration of activity from central and southern Alberta to other regions of the province has been significant,” says David Yager, a longtime oil and gas service company executive who now works as a special advisor to Alberta Premier Danielle Smith.

“For decades there were vibrant oil service communities in places like Medicine Hat, Taber, Brooks, Drumheller and Red Deer,” he says.

“These [oil service communities] have contracted materially with the new service centres growing in places like Lloydminster, Bonnyville, Rocky Mountain House, Edson, Whitecourt, Fox Creek and Grande Prairie.”

Fewer Wells and Fewer Rigs

Extended-reach horizontal drilling compared to shallow, vertical drilling enables more oil and gas production from fewer wells.

Outside the oil sands, in 2005, producers in Alberta drilled 17,300 wells. In 2023, that dropped to just 3,700 wells, according to AER data.

Despite that massive nearly 80 per cent decrease in wells drilled, total production of oil, natural gas and natural gas liquids outside of the oil sands is essentially the same today as it was in 2005.

Last year, non-oil sands production was 3.1 million barrels of oil equivalent (boe) per day, compared to 3.4 million boe per day in 2005–but from about 13,600 fewer new wells.

Innovation from drilling and energy services companies has been a major factor in achieving these impressive results, says Mark Scholz, CEO of the Canadian Association of Energy Contractors. But there’s been a downside.

Yager notes that much of the drilling and service equipment employed on conventional oil and gas development is not suited for unconventional resource exploitation.

Scholz says the productivity improvements resulted in an oversupply of rigs, especially rigs with limited depth ratings and limited capability for “pad” drilling, where multiple wells are drilled the same area on the surface.

Rigs have been required to drill significantly deeper wellbores than in the traditional shallow gas market, he says.

“This has resulted in rig decommissioning or relocations and a tactical effort to upgrade engines, mud pumps, walking systems and pipe-handling technology to meet evolving customer demands,” he says.

“You need not go beyond the reductions in Canada’s drilling rig fleet to understand the impact of these operational innovations. Twenty years ago, there were 950 drilling rigs; today, we have 350, a 65 per cent reduction. [And] further contractions are likely in the near term.”

Scholz says, “collaboration and partnerships between producers and contractors were necessary to make this transition successful, but the rig fleet has evolved into a much deeper, technologically advanced fleet.”

A Higher Cost of Entry

Yager says that along with growth in the oil sands, replacing thousands of new vertical shallow gas wells with fewer, high-volume extended-reach horizontal wells has made it more challenging for smaller companies to participate.

“The barriers to entry in terms of capital required have changed tremendously. At one time a new shallow gas well could be drilled and put on stream for $150,000. Today’s wells in unconventional plays cost from $3 million to $8 million each,” he says.

“This has materially changed the exploration and production companies developing the resource, and the type of oilfield services equipment employed. An industry that was once dominated by multiple smaller players is increasingly consolidating into fewer, larger entities. This has unintended consequences that are not well understood by the public.”

More Oil (Sands), Less Gas

Higher oil prices and horizontal drilling helped change Alberta from a natural gas hotbed to a global oil powerhouse.

In the oil sands, horizontal wells enabled a key technology called steam assisted gravity drainage (SAGD), which went into commercial service in 2001 to allow for a massive expansion of what is referred to as in situ oil sands production.

In 2005, mining dominated oil sands production, at about 625,000 barrels per day compared to 440,000 barrels per day from in situ projects. In situ oil sands production exceeded mining for the first time in 2013, at 1.1 million barrels per day compared to 975,000 barrels per day from mining.

Today the oil sands production split is nearly half and half. Last year, in situ projects–primarily SAGD–produced approximately 1.8 million barrels per day, compared to about 1.7 million barrels per day from mining.

Natural gas used to exceed oil production in Alberta. In 2005, natural gas provided 54 per cent of the province’s total oil and gas supply. Nearly two decades later, oil accounts for 60 per cent compared to 29 per cent from natural gas. The remaining approximately 11 per cent of production is natural gas liquids like propane, butane and ethane.

Alberta’s non-renewable resource revenue reflects the shift in activity to more oil sands and less natural gas.

In 2005, Alberta received $8.4 billion in natural gas royalties and $950 million from the oil sands. In 2023, the oil sands led by a wide margin, providing $16.9 billion in royalties compared to $3.6 billion from natural gas.

Innovation and Emerging Resources

As Alberta’s oil and gas industry continues to evolve, another shift is happening as investments increase into emissions reduction technologies like carbon capture and storage (CCS) and emerging resources.

Since 2015, CCS projects in Alberta have safely stored more than 14 million tonnes of CO2 that would have otherwise been emitted to the atmosphere. And more CCS capacity is being developed.

Construction is underway on an $8.9-billion new net-zero plant producing polyethylene, the world’s most widely used plastic, that will capture and store CO2 emissions using the Alberta Carbon Trunk Line hub. Two additional CCS projects got the green light to proceed this summer.

Meanwhile, in 2023, producers spent $700 million on emerging resources including hydrogen, geothermal energy, helium and lithium. That’s more than double the $230 million invested in 2020, the first year the AER collected the data.

“Energy service contractors are on the frontlines of Canada’s energy evolution, helping develop new subsurface commodities such as lithium, heat from geothermal and helium,” Scholz says.

“The next level of innovation will be on the emission reduction front, and we see breakthroughs in electrification, batteries, bi-fuel engines and fuel-switching,” he says.

“The same level of collaboration between service providers and operators that we saw in our productivity improvement is required to achieve similar results with emission reduction technologies.”

Agriculture

Lacombe meat processor scores $1.2 million dollar provincial tax credit to help expansion

Alberta’s government continues to attract investment and grow the provincial economy.

The province’s inviting and tax-friendly business environment, and abundant agricultural resources, make it one of North America’s best places to do business. In addition, the Agri-Processing Investment Tax Credit helps attract investment that will further diversify Alberta’s agriculture industry.

Beretta Farms is the most recent company to qualify for the tax credit by expanding its existing facility with the potential to significantly increase production capacity. It invested more than $10.9 million in the project that is expected to increase the plant’s processing capacity from 29,583 to 44,688 head of cattle per year. Eleven new employees were hired after the expansion and the company plans to hire ten more. Through the Agri-Processing Investment Tax Credit, Alberta’s government has issued Beretta Farms a tax credit of $1,228,735.

“The Agri-Processing Investment Tax Credit is building on Alberta’s existing competitive advantages for agri-food companies and the primary producers that supply them. This facility expansion will allow Beretta Farms to increase production capacity, which means more Alberta beef across the country, and around the world.”

“This expansion by Beretta Farms is great news for Lacombe and central Alberta. It not only supports local job creation and economic growth but also strengthens Alberta’s global reputation for producing high-quality meat products. I’m proud to see our government supporting agricultural innovation and investment right here in our community.”

The tax credit provides a 12 per cent non-refundable, non-transferable tax credit when businesses invest $10 million or more in a project to build or expand a value-added agri-processing facility in Alberta. The program is open to any food manufacturers and bio processors that add value to commodities like grains or meat or turn agricultural byproducts into new consumer or industrial goods.

Beretta Farms’ facility in Lacombe is a federally registered, European Union-approved harvesting and meat processing facility specializing in the slaughter, processing, packaging and distribution of Canadian and United States cattle and bison meat products to 87 countries worldwide.

“Our recent plant expansion project at our facility in Lacombe has allowed us to increase our processing capacities and add more job opportunities in the central Alberta area. With the support and recognition from the Government of Alberta’s tax credit program, we feel we are in a better position to continue our success and have the confidence to grow our meat brands into the future.”

Alberta’s agri-processing sector is the second-largest manufacturing industry in the province and meat processing plays an important role in the sector, generating millions in annual economic impact and creating thousands of jobs. Alberta continues to be an attractive place for agricultural investment due to its agricultural resources, one of the lowest tax rates in North America, a business-friendly environment and a robust transportation network to connect with international markets.

Quick facts

- Since 2023, there are 16 applicants to the Agri-Processing Investment Tax Credit for projects worth about $1.6 billion total in new investment in Alberta’s agri-processing sector.

- To date, 13 projects have received conditional approval under the program.

- Each applicant must submit progress reports, then apply for a tax credit certificate when the project is complete.

- Beretta Farms has expanded the Lacombe facility by 10,000 square feet to include new warehousing, cooler space and an office building.

- This project has the potential to increase production capacity by 50 per cent, thereby facilitating entry into more European markets.

Related information

Alberta

Alberta Next: Alberta Pension Plan

From Premier Danielle Smith and Alberta.ca/Next

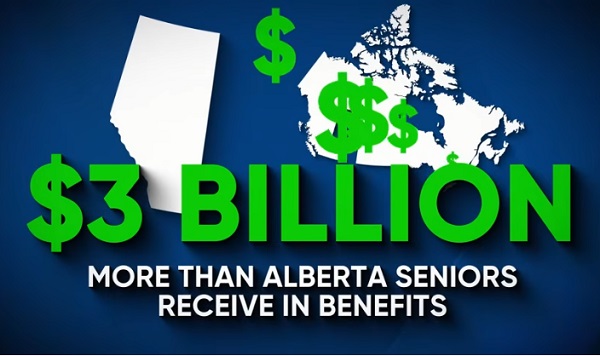

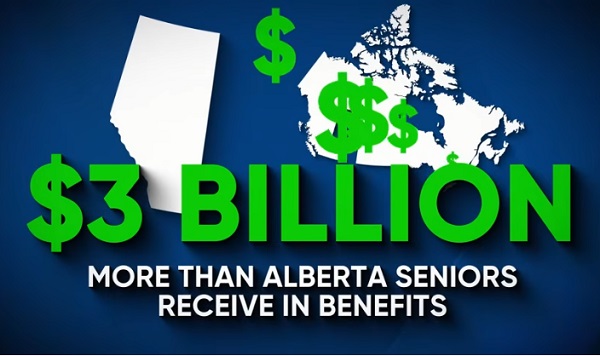

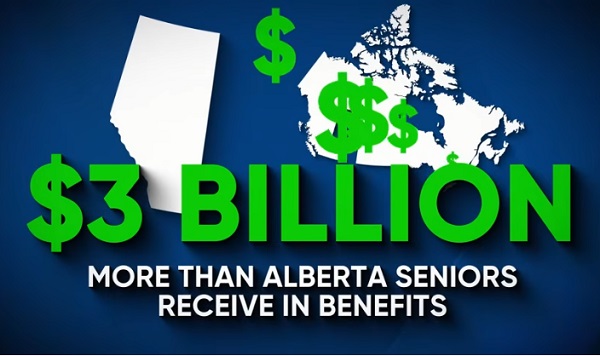

Let’s talk about an Alberta Pension Plan for a minute.

With our young Alberta workforce paying billions more into the CPP each year than our seniors get back in benefits, it’s time to ask whether we stay with the status quo or create our own Alberta Pension Plan that would guarantee as good or better benefits for seniors and lower premiums for workers.

I want to hear your perspective on this idea and please check out the video. Get the facts. Join the conversation.

Visit Alberta.ca/next

-

Agriculture2 days ago

Agriculture2 days agoCanada’s supply management system is failing consumers

-

Alberta1 day ago

Alberta1 day agoAlberta uncorks new rules for liquor and cannabis

-

Energy20 hours ago

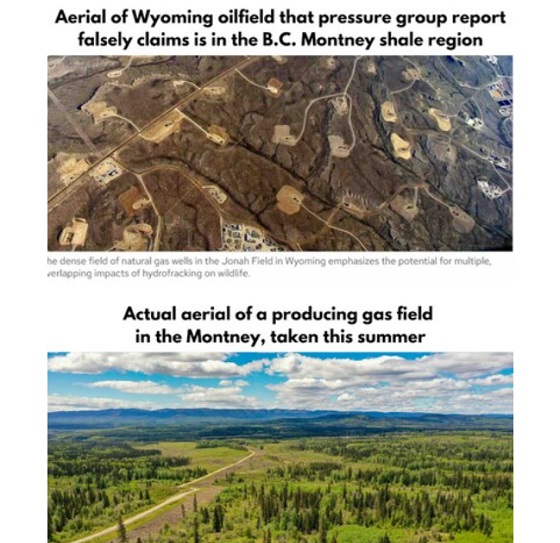

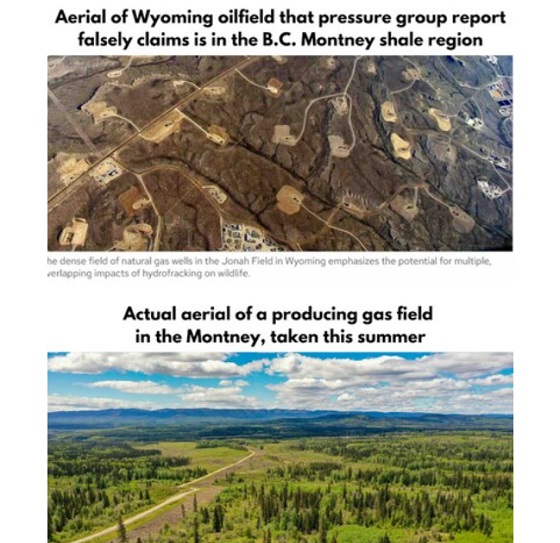

Energy20 hours agoB.C. Residents File Competition Bureau Complaint Against David Suzuki Foundation for Use of False Imagery in Anti-Energy Campaigns

-

COVID-1920 hours ago

COVID-1920 hours agoCourt compels RCMP and TD Bank to hand over records related to freezing of peaceful protestor’s bank accounts

-

Crime1 day ago

Crime1 day agoProject Sleeping Giant: Inside the Chinese Mercantile Machine Linking Beijing’s Underground Banks and the Sinaloa Cartel

-

International1 day ago

International1 day agoTrump transportation secretary tells governors to remove ‘rainbow crosswalks’

-

Alberta24 hours ago

Alberta24 hours agoAlberta Next: Alberta Pension Plan

-

C2C Journal17 hours ago

C2C Journal17 hours agoCanada Desperately Needs a Baby Bump